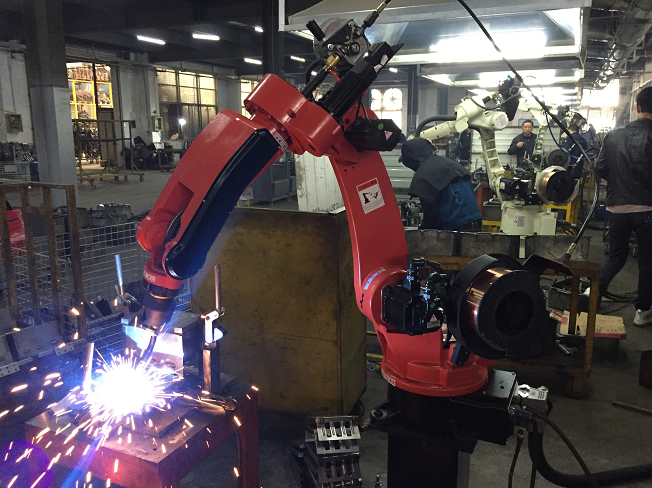

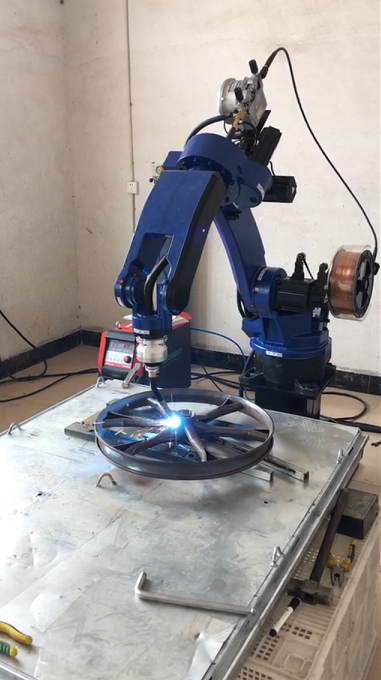

Kweli nqanaba, iirobhothi zokuwelda zisetyenziswe ngokubanzi kwimveliso yeemoto, ukuwelda kombane kwi-chassis, imizobo yesihlalo samathambo, iireyile zesilayidi, iimufflers kunye neziguquli zabo zetorque, njl.sebenzisa.

Iinkampani zeemoto ziye zagqiba ekubeni zixhobise ukuwelda njengesiqhelo, zisebenzisa olu hlobo lwetekhnoloji ukuphucula umgangatho we-welding yombane, kwaye zizama ukuyisebenzisa ukuze zibuyisele imisebenzi ye-arc welding.Ixesha elingaphakathi kumgca omfutshane nalo lincitshiswe kakhulu.Kutshanje kukhululwe irobhothi ye-welding ene-low aspect ratio, esetyenziselwa ukuwelda amalungu asezantsi omzimba ngokuwelda kombane.Olu hlobo welding elifutshane irobhothi ezikrelekrele zinokudityaniswa kunye iirobhothi ezinde ukuvelisa kunye nenkqubo isiphelo eliphezulu umzimba, ngaloo ndlela ukunciphisa ubude umgca imveliso welding yombane yonke.

Uninzi lweendawo ze-chassis zemoto ezifana ne-axle yangasemva, i-sub-frame, i-crank arm, i-suspension system, i-shock absorber, njl. njl. eveliswayo kufuneka ibe yinkxaso yenkxaso yokhuseleko elawulwa yindlela ye-MIG welding.Yi 1.5 ~ 4mm.Isitshixo se-welding yombane silawulwa yi-lap joints kunye ne-fillet joints.Umgangatho we-welding yombane kunye ne-welding iphezulu kakhulu, kwaye umgangatho wayo unobungozi kwizinto ezikhuselekileyo zemoto.Emva kokuba i-robot ye-welding isetyenzisiwe, ukubonakala kunye nomgangatho obalulekileyo we-weldment kuphuculwe ngakumbi, kwaye ukuthembeka komgangatho kuqinisekiswa, ukusebenza kakuhle kwabasebenzi kuyancipha, kwaye indawo yabasebenzi iyaphuculwa.

Ixesha lokuposa: Mar-21-2022