I-Robotic Mig welding---Isisombululo sokuwelda sesibane sesitalato

Isalathiso

1. Ulwazi malunga nomsebenzi

2. Robotic welding Solution Overview

3. I-Robotic welding Solution Inkqubo

4. ULungiselelo lweZixhobo zeRobhothi

5. UMsebenzi oPhambili 6. Ukuqaliswa kweZixhobo

7. Ukufakela, ukuKhomishini noQeqesho

8. Khangela kunye noKwamkeleka

9. IiMfuno zokusiNgqongileyo

10. Iwaranti kunye nenkonzo yasemva kokuthengisa

11. Ukuhanjiswa kwamaxwebhu aqhotyoshelweyo

Ividiyo yeSicelo seRobotic welding

1, Ulwazi loMsebenzi

-I-Welding wire DiameterФ1.2mm

-Inkqubo yokuwelda: ukuwelda okukhuselwe yigesi / ukuwelda kweMig

-Uhlobo lwe-weld seam: uhlobo lomgca othe ngqo, uhlobo lwesangqa

-Ukukhusela igesi:99% CO2

-Indlela yokusebenza: ukulayisha ngesandla kunye nokukhulula, i-robot ye-welding automatic

-Imposiso yokuFaka:≤ 0.5mm

-Ukucoca ipleyiti :ukukhazimla metallic kunokubonwa weld kunyephakathi kobude obuphindwe kabini bomthungo we-weld kumacala omabini

I-2, isisombululo se-Robotic welding Overview

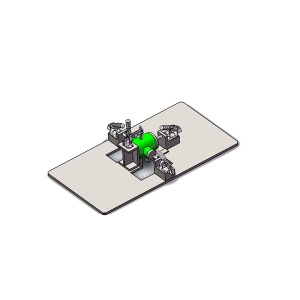

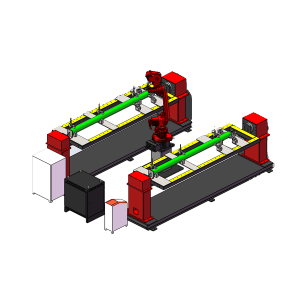

Ukuze kuphuculwe ukusebenza kakuhle, ngokwemeko yokwenyani ye-workpiece, i-Honyen factory iya kunika isethi ye-robot ye-welding workstation, enokuthi ithathelwe indawo ngezixhobo ezahlukeneyo ukuze ihambelane neemveliso ezahlukeneyo.Indawo yokusebenza yenziwe yimodeli yerobhothi: HY1006A-145 irobhothi yokuwelda, umthombo wamandla wokuwelda, itotshi ekhethekileyo yerobhothi, iKhabhinethi yolawulo lombane kunye namaqhosha, i-chiller yokupholisa amanzi, izikhundla eziphindwe kabini zesikhululo sokusebenza, izixhobo zezixhobo, ucingo lokhuseleko (ukhetho) kunye nezinye. iinxalenye.

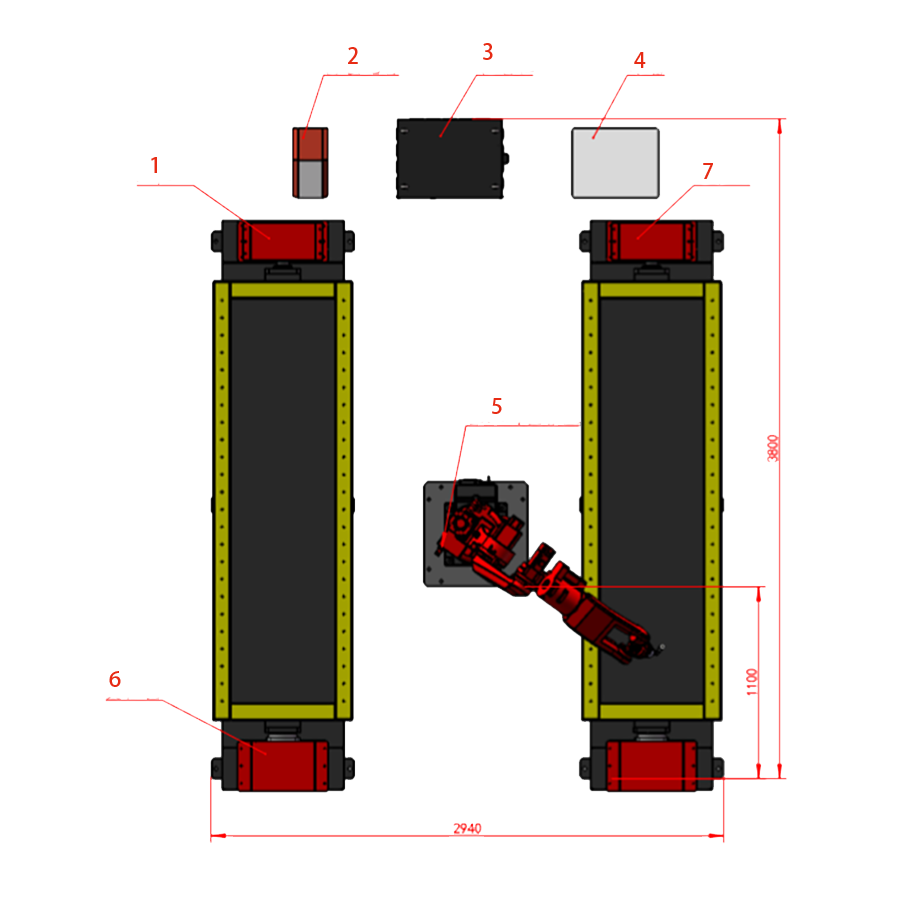

3, Mig Welding indawo yokusebenza yerobhothi Ukuqaliswa koLwayo

Honyen irobhothi arc welding workstation Uyilo

1, Isikhululo sokusebenza 1

2, umthombo Welding Power

3, Umlawuli weRobhothi

I-4, i-chiller yokupholisa amanzi

5, Honyen arc welding Robot, HY1006A-145

6, uMbonisi

7, Isikhululo sokusebenza 2

Amalungu eepali zombane

Amalungu eepali zombane 2

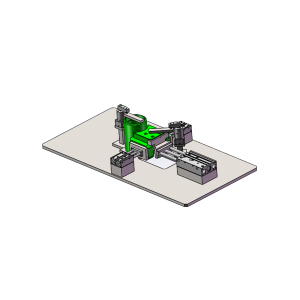

Izisombululo zerobhothi zewelding Uyilo 1

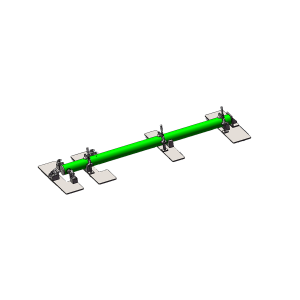

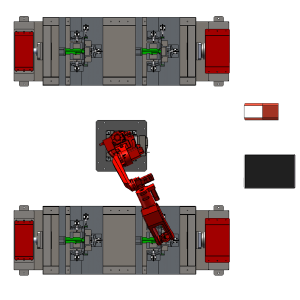

ULungiso lwezahlulo zePali yoMbane 3

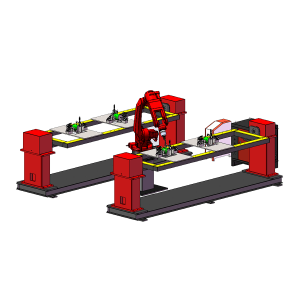

Izisombululo zerobhothi zewelding Uyilo 2

Izisombululo zerobhothi zewelding Uyilo 3

4. I-Robotic welding Solution Inkqubo I. Umsebenzisi ulayisha i-workpiece kwisikhululo soku-1, Emva kokuyilayisha kunye nokuyibamba.Umsebenzisi ucinezela iqhosha lokuqala logcino lwerobhothi 1, kwaye irobhothi iqala ukuwelda okuzenzekelayo;

II.Umsebenzisi uya kwisikhululo sesi-2 sokulayisha i-workpiece.Emva kokulayisha i-workpiece, i-Operator icofa i-robot yokugcina iqhosha lokuqala 2 kwaye ilinde i-robot igqibe ukuwelda;

III.Emva kokuba irobhothi igqibe ukuwelda kwisikhululo soku-1, yenza ngokuzenzekelayo inkqubo yesitishi sesi-2;

Ⅳ.Emva koko uMsebenzi wothula iWorkpiece kwisikhululo soku-1 kwaye alayishe umsebenzi omtsha;

V. umjikelo ngokulandelelana.

5. ULungiselelo lweZixhobo zeRobhothi

| Into | Umzekelo | Ubungakanani | Uphawu | Amagqabantshintshi | ||

| 1 | 1.1 | Umzimba werobhothi | HY1006A-145 | Iseti e-1 | Honyen | Kubandakanya umzimba werobhothi, iKhabhinethi yolawulo, umdwelisi wokufundisa |

| 1.2 | Ikhabhinethi yolawulo lwerobhothi | Iseti e-1 | ||||

| 1.3 | Welding umthombo wamandla | Iseti e-1 | Honyen | Megmeet welder | ||

| 1.4 | itanki yamanzi | Iseti e-1 | Honyen | |||

| 1.5 | Ukupholisa amanzi kwiTotshi ye-welding | Iseti e-1 | Honyen | |||

| 2 | 1 iAxis positioner | HY4030 | 2 Seta | Honyen | 2.5m, 300kg umthwalo, 1.5KW rated imveliso amandla | |

| 3 | Isikhululo solawulo lombane | 2 Seta | Honyen | |||

| 4 | Uyilo lwenkqubo, ukudibanisa kunye nokucwangcisa | Iseti e-1 | Honyen | |||

| 5 | Ucingo lokhuseleko | Iseti e-1 | Honyen | Ukhetho | ||

6. Umsebenzi ophambili Ukuqinisekisa umgangatho we-welding kunye nokusebenza kakuhle, inkqubo yerobhothi ixhotyiswe ngomsebenzi ogqibeleleyo wokuzikhusela kunye ne-arc welding database.Imisebenzi ephambili yile ilandelayo:

Qhubeka nendlela yokuqala: xa i-shield gas flow flow ingaqhelekanga, i-welding wire idliwe kwaye imisiwe okwethutyana ngexesha le-welding, umyalelo othi "qhubeka u-welding" unokubizwa ngokuthe ngqo emva kokujongana neengxaki, kwaye i-robot inokuqhubeka ngokuzenzekelayo i-welding ukusuka kuyo nayiphi na indawo ukuya kwindawo emisiwe.

Ukubona iimpazamo kunye nokuqikelela: emva kokuba i-alam yenzekile, iRobhothi ifumana idatha kwisixhobo solawulo, icinge ngeendawo ezinempazamo, kwaye inike uluhlu lwamacandelo aneempazamo ngokulandelelana, ibonise ukulandelelana kwamacandelo okutshintshwa kunye nokuxilongwa kwikhompyuter, enokuthi ijongwe kwindawo enependant yokufundisa.Ukongeza, ikhomputha rhoqo Fumana idatha yokusebenza kwirobhothi, hlalutya idatha efunyenweyo, gweba ukuba imeko yerobhothi iqhelekile, kwaye ukhawuleze umsebenzisi ukujongana nempazamo ezayo.

Anti-ungquzulwano umsebenzi: xa i-robot welding torch yenza ingozi kunye nezinto zangaphandle, isixhobo sokulwa ne-robot sisebenza ukukhusela i-welding Torch kunye nomzimba werobhothi.

Ugcino lweenkcukacha zengcaphephe: ngokubeka iimeko eziyimfuneko zokuthunga kwiprogram, le nkqubo inokugqiba ngokuzenzekelayo ukulungiswa kwe-weld seam kunye nokulungelelaniswa kweeparitha ze-welding ezihambelanayo.

Ukufundisa kunye nokucwangcisa: qaphela inkqubo ekwisiza ngokusebenzisa ipendant yokufundisa.

Welding welding: ngexesha welding inkqubo, Robot ayikwazi kuphela ukuqaphela ujingi eqhelekileyo uhlobo ngeenxa zonke kwaye Kananjalo uhlobo Z.Oku kunceda irobhothi ukuba iqonde umsebenzi we-welding womthengi ngokwemilo yeqhekeza lomsebenzi, ukuze kwandiswe ububanzi bomthungo we-weld ngamandla wokuwelda kunye nokusebenza kakuhle kwe-welding.

Umboniso wesimo: irobhothi ingabonisa ubume bokusebenza kwenkqubo yerobhothi ngokufundisa ipendant, kubandakanywa ubume bokusebenza kwenkqubo, utshintsho lweparameter yenkqubo yewelding, utshintsho lweparameter yenkqubo, indawo yangoku yerobhothi, iirekhodi zembali yokwenziwa, imiqondiso yokhuseleko, iirekhodi ze-alam, njl. njl., ukuze abathengi bakwazi ukuqonda kwangexesha imeko yerobhothi kwaye uthintele iingxaki kwangaphambili.

Iifayile zegalelo / imveliso: Iifayile zenkqubo yerobhothi kunye neefayile zenkqubo kwinkqubo yerobhothi zinokugcinwa kwikhadi le-SD ngaphakathi kwisilawuli seRobhothi, kwaye zingagcinwa kwizixhobo zangaphandle.Iinkqubo ezibhalwe yi-software yeprogram engaxhunyiwe kwi-intanethi nazo zingalayishwa kumlawuli we-Robot, Oku kunceda abathengi bagcine iifayile zenkqubo rhoqo, Emva kokuba kukho ingxaki kwinkqubo yerobhothi, Ezi zigcino zingabuyiselwa ukusombulula iingxaki zerobhothi.

7, Ukuqaliswa kweZixhobo I-HY1006A-145 yirobhothi esebenza kakhulu enomsebenzi okrelekrele.Ifanelekile kwi-gas shielded welding kunye nezicelo zokusika.Iimpawu zayo bubunzima obulula kunye nesakhiwo esihlangeneyo.

Ukusetyenziswa kwe-arc welding, i-Honyen iye yaqulunqa ngempumelelo ubunzima obulula kunye nengalo edibeneyo, engaqinisekanga kuphela ukuthembeka kwasekuqaleni, kwaye iqonda ukusebenza kweendleko eziphezulu.

I-Honyen yamkela eyona teknoloji ye-servo iphezulu, enokuphucula isantya sokuhamba kunye nokuchaneka kwerobhothi, ukunciphisa ukungenelela kwabaqhubi, kunye nokuphucula ukusebenza kakuhle kwi-welding ekhuselwe yigesi kunye nokusika.

| I-axis | Ukuhlawula | Ukuphindaphinda | Umthamo wamandla | Okusingqongileyo | Ubunzima | Ukuhlohla |

| 6 | 10 | 0.08 | 6.5KVA | 0 ~ 45℃20~80%RH(Akukho Kufuma) | 300kg | Umhlaba/Isilingi |

| Uluhlu olushukumayo J1 | J2 | J3 | J4 | J5 | J6 | Inqanaba le-IP |

| ±170° | +80°~-150° | + 95 ° ~-72 ° | ±170° | +115 ° ~-140 ° | ±220° | IP54/IP65(isandla) |

| Isantya esiphezulu J1 | J2 | J3 | J4 | J5 | J6 | |

| 158°/s | 145°/s | 140°/s | 217°/s | 172°/s | 500°/s |

Ujongano olupheleleyo lwesiTshayina kwaye lunokutshintshwa lube kwisiNgesi ngokusebenza okugcweleyo kwekhibhodi

Ixhasa unxibelelwano olwahlukeneyo olubandakanya ujongano lwe-I / O, i-Modbus, i-Ethernet njl.

Uqhagamshelwano lwenkxaso kunye neerobhothi ezininzi kunye nezinye izixhobo zangaphandle

Ubungakanani obukhulu besikrini esichukumisayo esinemibala

Isixhobo esilungelelanisiweyo sokuthintela ukungqubana, ukukhusela ingalo yerobhothi kunye nokunciphisa ukuphazamiseka

Ulawulo lweRobhothi lweMotion lubonelela ngesicwangciso sendlela esisiso

Amakhulu iingxowa umsebenzi eyakhelwe-ngaphakathi kunye nemisebenzi lula inkqubo

Ngekhadi le-SD, kukulungele ukugcina kunye nokukopa idatha

Isikhundla

I-Honyen Head-tail double support positioner esetyenziselwa ukujikelezisa i-workpiece, ukusebenzisana nerobhothi, ukufikelela kwindawo elungileyo yokuwelda kunye nokufezekisa ukusebenza kakuhle kwe-welding

Welding Power umthombo

I-Megmeet Ehave cm 500h / 500 / 350 uthotho olugcweleyo lwedijithali umthwalo onzima wedijithali * CO2 / MAG / MMA umatshini wokuwelda okrelekrele

8. Ukufakela, ukuKhomishini noQeqesho

Ngaphambi kokunikezelwa, inkqubo yerobhothi iya kuhlanganiswa kwaye ivavanywe ngokupheleleyo kwinkampani yethu.Umthengi uya kuzisa iinxalenye zabo kwinkampani yethu ukuze avavanye ukuwelda kunye nokwamkelwa kwangaphambili ngaphambi kokuhanjiswa.Ngexesha lokwamkelwa kwangaphambili, abaSebenzisi boMthengi baya kufumana uqeqesho lokuqala lobuchwephesha.

Isicwangciso sofakelo kunye neemfuno zobugcisa ziya kungeniswa kumthengi kwiintsuku ezili-15 ngaphambi kofakelo, kwaye umthengi uya kwenza amalungiselelo kwangexesha ngokweemfuno.Inkampani yethu iya kuthumela iinjineli ukuba zenze ufakelo lwenkqubo kunye nokugunyaziswa kwindawo yomsebenzisi.Phantsi komqathango wokuba umthengi uqinisekisa i-workpieces eyaneleyo yokugunyazisa, ixesha ukusuka kwi-programming commissioning, uqeqesho lwabasebenzi ukuya kwimveliso yovavanyo olukhulu aluyi kudlula iintsuku ezili-10.Inkampani yethu iqeqesha abasebenzisi benkqubo yerobhothi, ukusebenza kunye nokugcinwa kwabathengi, kwaye abaqeqeshwayo kufuneka babe nolwazi olusisiseko lwekhompyuter.

Ngexesha lofakelo kunye nokugunyaziswa, umthengi uya kubonelela ngezixhobo eziyimfuneko, ezifana nokuphakamisa izixhobo, i-forklift, iintambo, i-drill drill, njl., kunye nokubonelela ngoncedo lwexeshana ngexesha lokukhulula kunye nokufakwa.

Inkampani yethu inoxanduva lokukhokela, ukufakwa, ukugunyaziswa kwezixhobo kunye noqeqesho lomsebenzisi.Inkampani yethu inoxanduva lokugcina kunye noqeqesho lokusebenza.Umsebenzisi uya kusebenzisa kwaye agcine isixhobo ngokwaso.Imixholo yoqeqesho: umgaqo wesakhiwo sezixhobo, ukujongana neengxaki zombane eziqhelekileyo, isingeniso kwimiyalelo yeprogram esisiseko, izakhono zokucwangcisa kunye neendlela zokucwangcisa iinxalenye eziqhelekileyo, isingeniso kunye nezilumkiso zepaneli yokusebenza kwezixhobo, ukusebenza kwezixhobo zokusebenza, njl.

9. Khangela kunye nokwamkelwa

Ukwamkelwa kwangaphambili kuqhutyelwa kwinkampani yethu ngokuthatha inxaxheba kwabasebenzi abafanelekileyo bamaqela omabini.Ngexesha lokuvunywa kwangaphambili, ii-workpieces ziya kuvavanywa ngokuchaneka kwe-workpiece ebonelelwe ngumthengi, Kuphela i-workpiece eqeqeshiweyo eya kuthi idityaniswe, kwaye ingxelo yovavanyo lwangaphambi kokuvunywa iya kukhutshwa.Emva kokwamkelwa kokugqiba, iRobhothi iya kuhanjiswa.Ukuqinisekisa ukwamkelwa kwangaphambili, ii-workpieces ezi-3 ziya kubonelelwa ngemveliso eqhelekileyo.

10.IiMfuno zokusiNgqongileyo Iimfuno zokhuseleko: igesi kunye nezixhobo ezisetyenziswa ngabasebenzisi kufuneka zihambelane nemigangatho yelizwe efanelekileyo.

Umthombo womoya uya kumiselwa ngaphandle, ungabi ngaphantsi kwe-15m kude nomlilo, kwaye ungabi ngaphantsi kwe-15m kude nerhasi neoksijini.Umthombo womoya uya kugcina iimeko ezilungileyo zokungenisa umoya kwaye ube kwindawo epholileyo kude nomoya.

Zonke iisekethe zegesi kufuneka zitshekishwe phambi kokusebenzisa irobhothi.Ukuba kukho ukuvuza komoya, kufuneka kulungiswe ukuqinisekisa ukuba akukho mpazamo.

xa ulungisa uxinzelelo kunye nokutshintsha i-cylinder yegesi, umqhubi akayi kuba nezinto zeoli ezandleni zakhe.

ukufuma kwe-ambient: ngokubanzi, ukufuma kwe-ambient yi-20% ~ 75% RH (kwimeko yokungaxinzeki);Ixesha elifutshane (ngaphakathi kwenyanga ye-1) ngaphantsi kwe-95% ye-RH (izihlandlo ngaphandle kwe-condensation).

umoya oxinanisiweyo: 4.5 ~ 6.0 kgf / cm2 (0.45-0.6mpa), ioli yokucoca kunye namanzi, ≥ 100L / min

Isiseko: ubuncinci amandla ekhonkrithi yiC25, kwaye ubuncinci besiseko buyi-400 mm

vibration: Zigcine kude kumthombo wokungcangcazela

Ubonelelo lwamandla: unikezelo lwamandla kuzo zonke izixhobo ezenziweyo zombane neze-elektroniki zisebenzisa i-50Hz (± 1) kunye ne-380V (± 10%) yombane wesigaba sesithathu se-AC ukuqinisekisa ukunikezelwa kombane okusisiseko.

Kwisayithi iinkonzo ezibonelelwa ngabathengi:

onke amalungiselelo ayimfuneko ngaphambi kokunikezelwa, njengesiseko, umsebenzi we-welding ofunekayo, ukulungisa izixhobo ezincedisayo, njl.

ukukhulula kunye nokuthuthwa kwindawo yomthengi.

11. Iwaranti kunye nenkonzo yasemva kokuthengisa Ixesha lewaranti yomthombo wamandla we-weld ziinyanga ezili-12.

Ixesha lewaranti yomzimba werobhothi ziinyanga ezili-18.

Kwimeko yokungaphumeleli okanye umonakalo phantsi kokusetyenziswa okuqhelekileyo kunye nezixhobo zingaphakathi kwexesha lewaranti, inkampani yethu inokulungisa okanye ithathe indawo yamalungu ngaphandle kwentlawulo ye-EXW (ngaphandle kwezinto ezidliwayo, iimveliso zokulondoloza, iityhubhu zokhuseleko, izibane zesalathisi kunye nezinye izinto ezisetyenziselwa ngokukodwa ezikhethwe yinkampani yethu).

Kwiindawo ezisesichengeni ngaphandle kwewaranti, inkampani yethu ithembisa ubomi benkonzo eqhelekileyo kunye nexabiso lokubonelela ngamacandelo asemngciphekweni, kwaye izixhobo zinejelo elizinzileyo lokubonelela ngezixhobo ukuya kuthi ga kwiminyaka emihlanu.

Ngaphandle kwexesha lewaranti, inkampani yethu iya kuqhubeka nokubonelela ngenkonzo ehlawulweyo ubomi bonke kwaye ibonelele ngenkxaso ebanzi yobugcisa kunye nezixhobo ezifunekayo.

12. Unikezelo oluqhotyoshelweyo loxwebhu Imizobo yokufakela: imizobo yokwakha isiseko sezixhobo kunye nemizobo yokufakela izixhobo

◆ imizobo yokuyila: i-fixture kunye nemizobo yezixhobo

◆ Incwadi ye-Manual: i-manual yokusebenza kwezixhobo, i-manual yokugcinwa kunye ne-robot manual manual

◆ izincedisi: uluhlu lonikezelo, isatifikethi kunye nekhadi lewaranti.