Isikhululo sokucoca iRobotic Gun

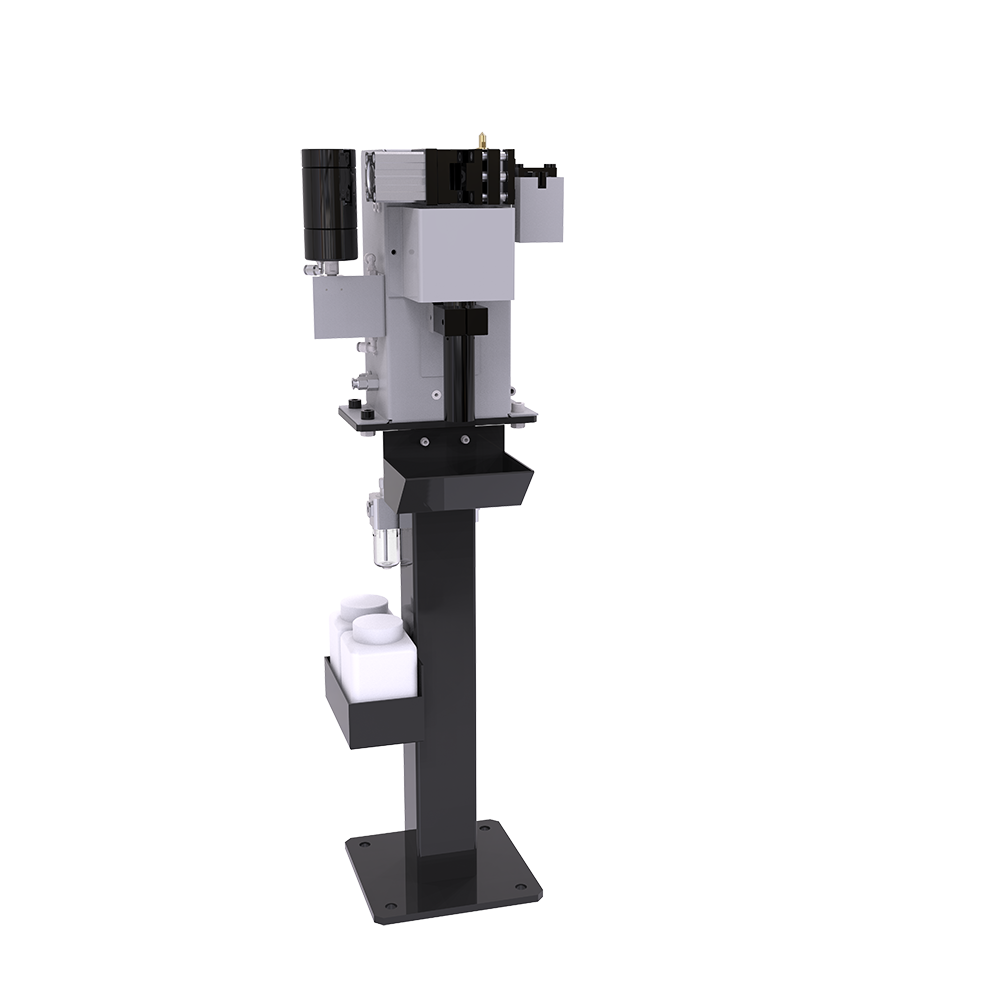

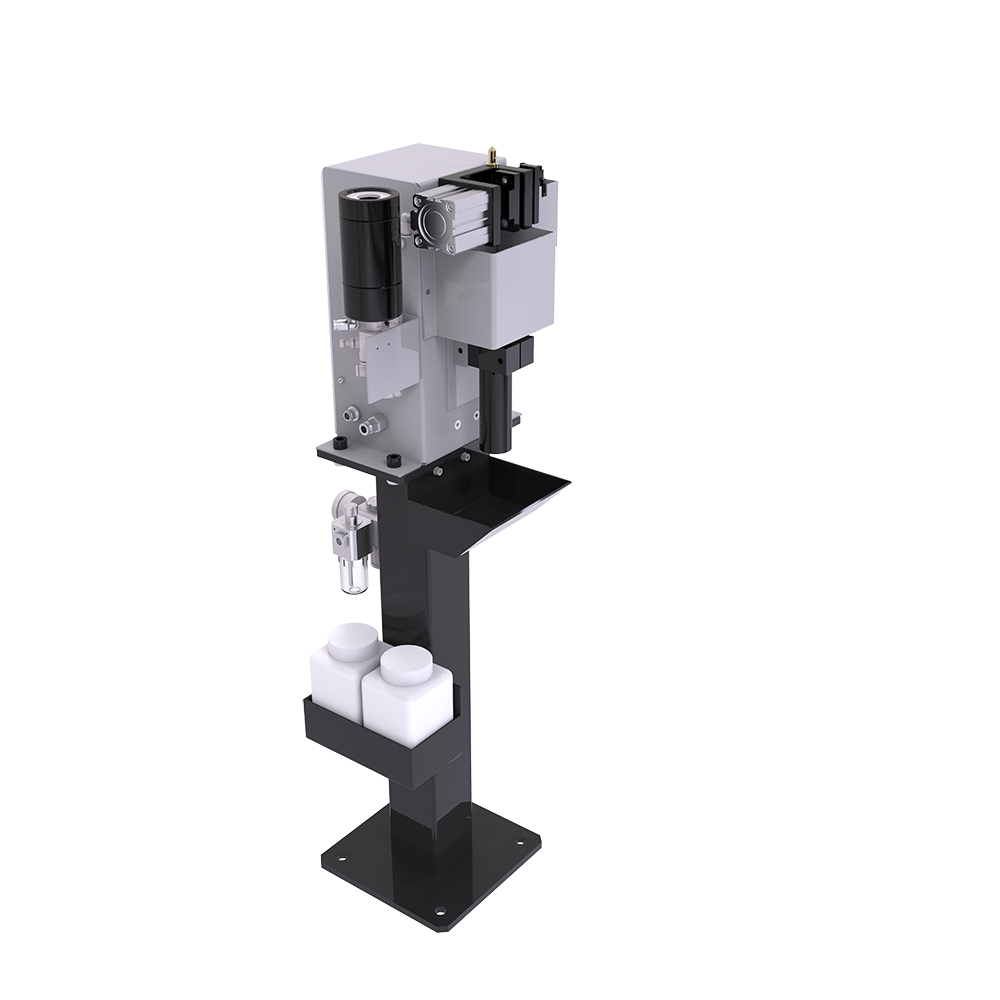

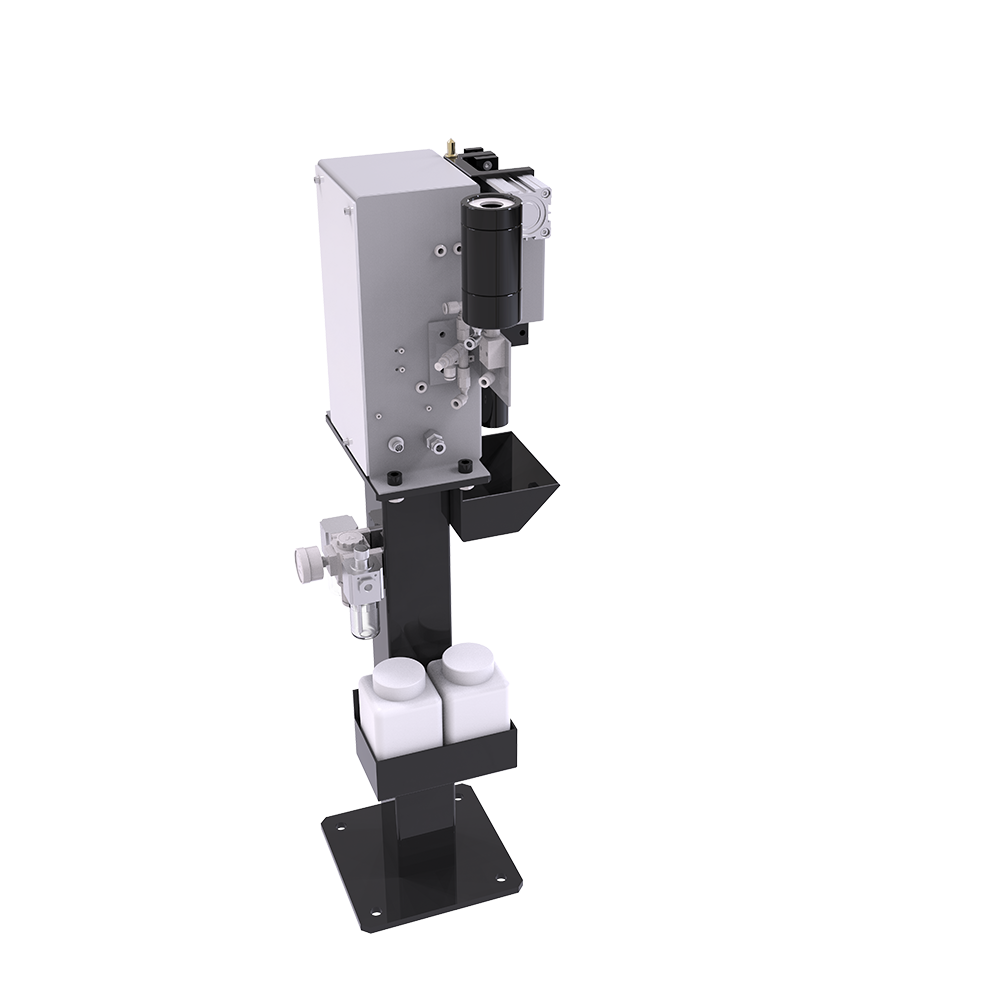

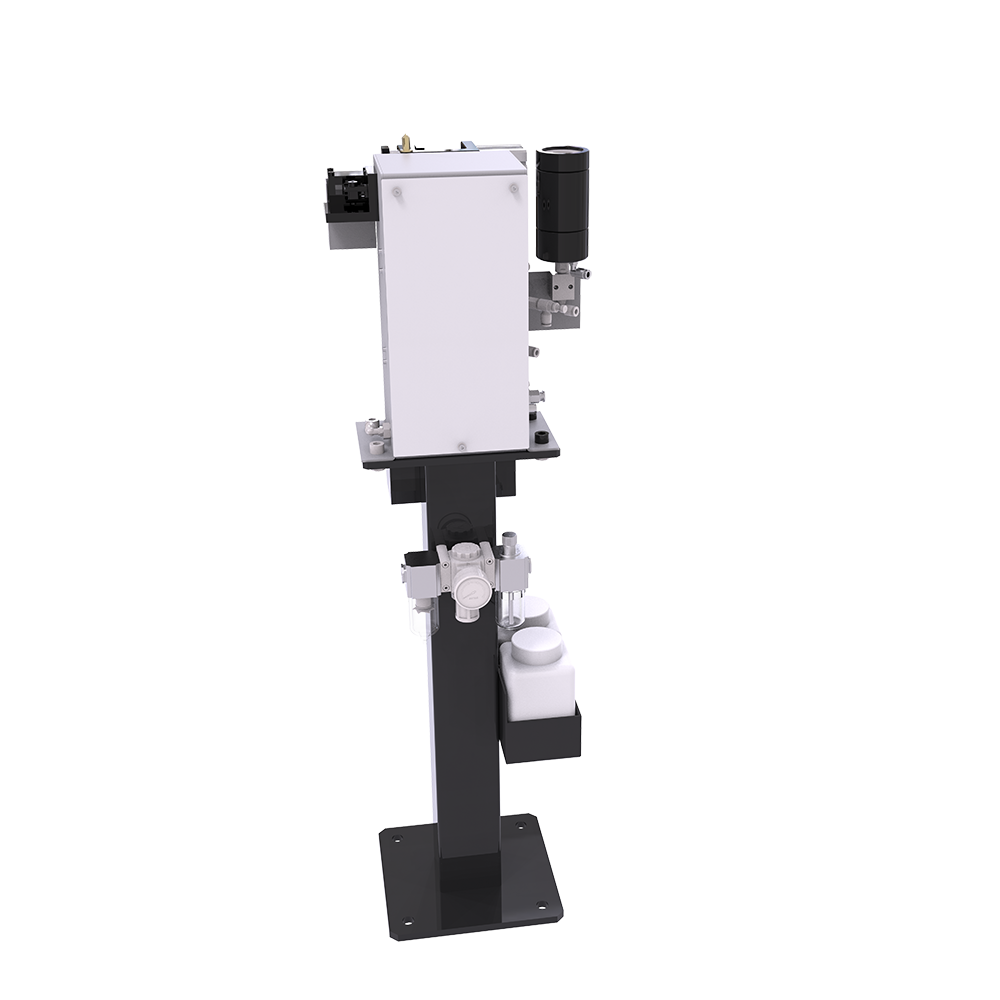

Intshayelelo yeMveliso

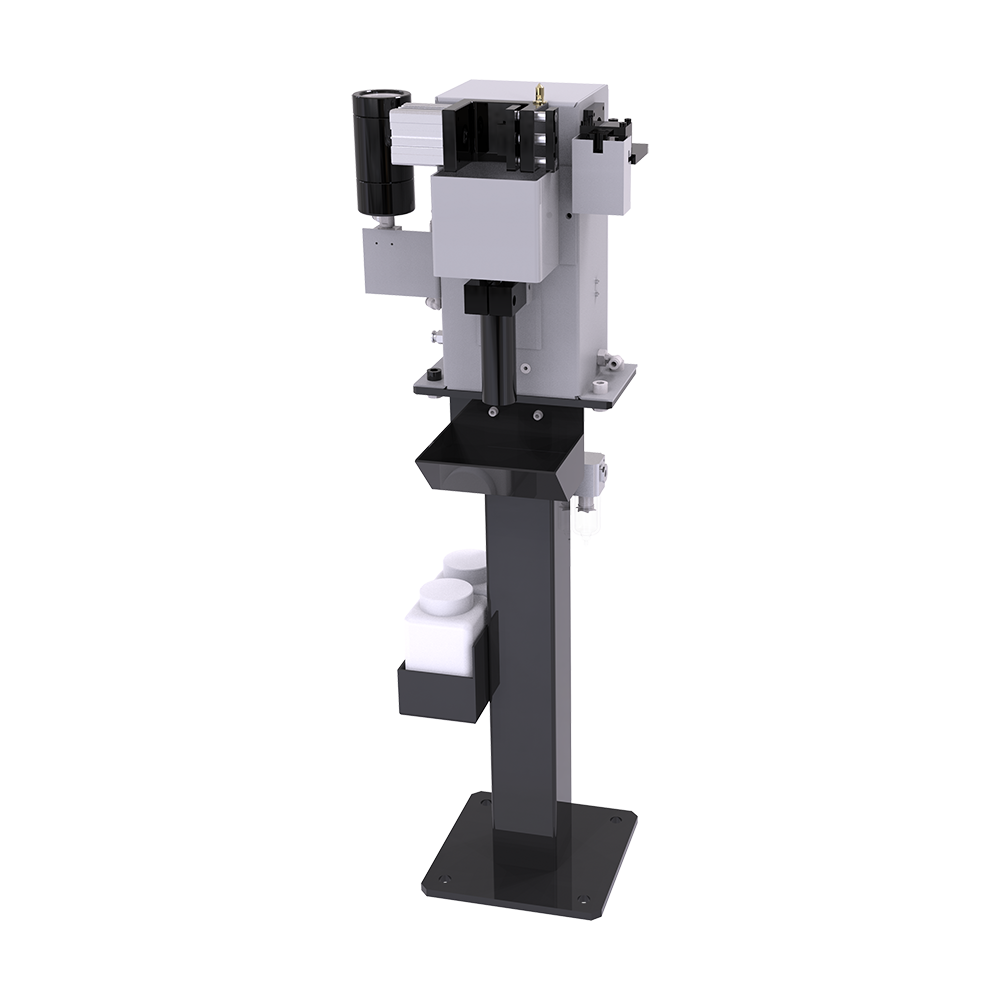

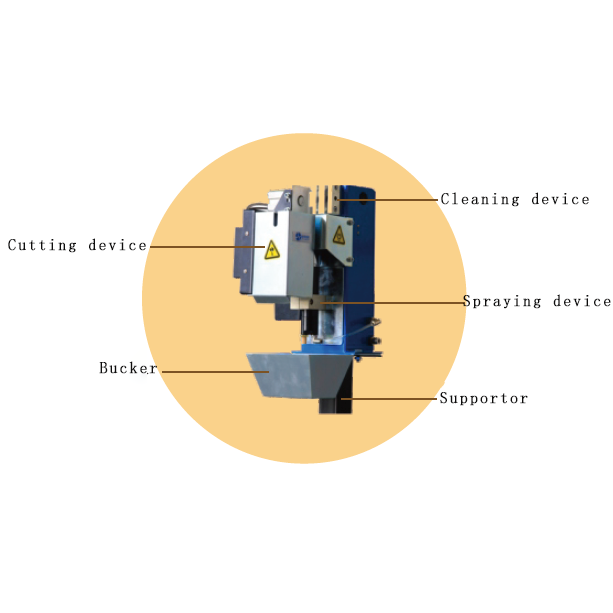

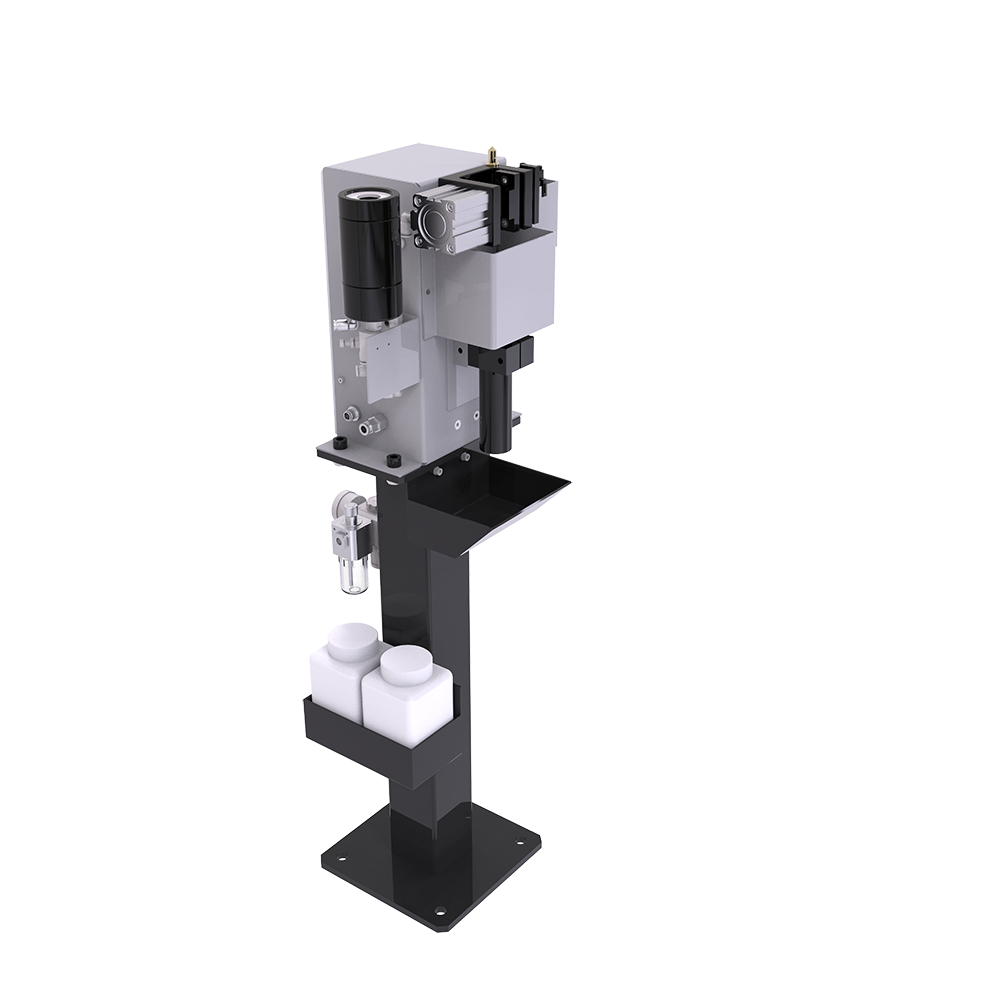

Isikhululo sokucoca ngokuzenzekelayo senzelwe i-robot welding gun kunye ne-othomathikhi ye-welding gun exhotywe nge-auto welding system.Ukusebenza kwezixhobo kulawulwa yi-robot, kwaye izixhobo ziya kunika umqondiso wempendulo ehambelanayo kwi-robot.

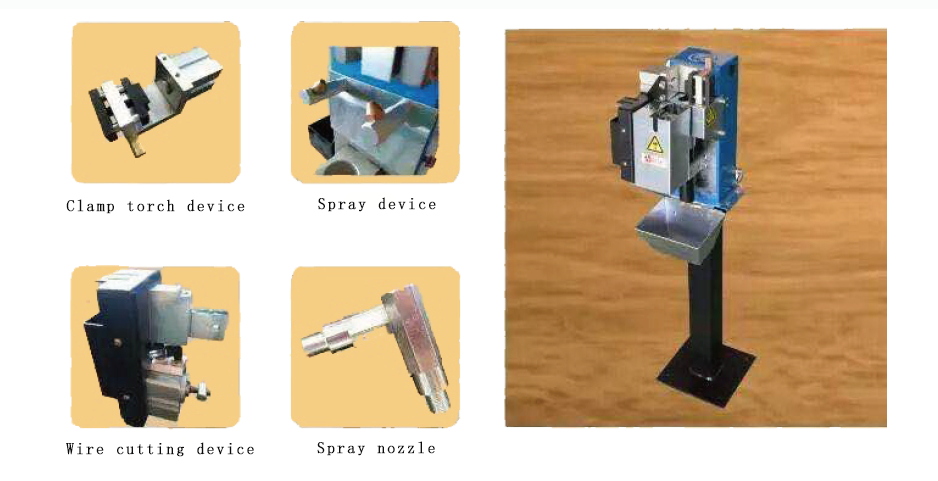

Isikhululo sokucoca sisebenzisa i-reamer rotation ukususa i-welding slag kunye nokungcola kwi-welding Torch head kunye ne-welding Torch nozzle.Isikhululo sokucoca sixhotyiswe ngesakhiwo esipheleleyo se-oil injection, intloko ye-welding Torch inokutshiza i-anti-splash liquid emva kokugqitywa kokucoca, ngoko ke njengokunciphisa amathuba okubambelela kwakhona kwe-welding slag.Ikwaxhotyiswe kunye nesixhobo sokusika ucingo oluzenzekelayo, olubangelwa ngumbane ngumlawuli we-robot okanye owenziwe ngoomatshini yitotshi ye-welding.

Iiparamitha zeTekhnoloji

| Umzekelo | HY2000S |

| Umoya oxinanisiweyo | Umoya owomileyo ongenawoli |

| Ubungakanani bomoya ofunekayo | Iilitha ezili-10 ngesekhondi |

| ulawulo lwenkqubo | umoya |

| I-Voltage | 24 |

| Ixesha lokucoca | 4 ~ 5 Okwesibini |

| Anti-splash umthamo | 500ml |

| Isixa senaliti yokuchaphaza | Iyahlengahlengiswa |

| Ubunzima | 14kg |

Iimbonakalo

Zonke iimveliso ezikumgangatho ophezulu

1. Ukucoca kunye noyilo lwenaliti ye-oyile kwindawo efanayo yendlela yokusika yeTotshi yokucoca, i-robot idinga kuphela isignali enye yokugqiba ukucoca kunye nesenzo sokutofa kweoli.

2. Isikhululo sokucoca sifuna kuphela imizuzwana ye-6-7 ukugqiba yonke inkqubo yokucoca, xa kuthelekiswa nezinye iimveliso ezifanayo kwimizuzwana ye-12, egcina kakhulu ixesha lokucoca i-robot kunye nokuphucula ukusebenza kakuhle kwerobhothi.

3. Ukusetyenziswa kwe-multifunctional reamer, itotshi yokucoca inokuba yingcambu yesiphumo sokucoca isihlalo somlomo ngokucokisekileyo.

4. Izinto eziphambili zokucoca i-Torch wire cutting mechanism ikhuselwe ngumgangatho ophezulu we-casing, ongenayo impembelelo ye-splash kunye nothuli.

5. Uhlobo olutsha lwesixhobo sokutofa kwe-oyile kwisikhululo sokucoca itotshi silawulwa yirobhothi ngevalve ye-solenoid.

6. I-arhente ye-atomizing ekhuselekileyo neyithembekileyo ye-anti-splash inokufikelela kwingcambu yentloko yetotshi ye-welding kakuhle.Kwangaxeshanye, igumbi lokutofa ioyile elivaliweyo liyinciphisa kakhulu ingxaki yongcoliseko lwe-oyile xa kuthelekiswa noyilo oludala.

7. Isixhobo sokusika ucingo silawulwa yi-valve ye-solenoid, kwaye ukusika ucingo kuchaneke ngakumbi. Qinisekisa ukuba ucingo olusikiweyo luwela kwibhokisi yokuqokelela xa kuthelekiswa nezinye iimveliso ze-brand, ukuhlelwa kombane kulula kakhulu, zonke izinto zokulawula zibekwe ngokukhuselekileyo. kwimeko, kwaye kukho imibhobho embalwa kakhulu eveziweyo

INKCAZELO BONISA

Zonke iimveliso ezikumgangatho ophezulu

ISIQINISEKISO

Ukuqinisekiswa komgangatho osemthethweni

FQA

Q. Ingaba indawo yakho yokucoca iNozzle ingasetyenziselwa zonke iirobhothi?

A. Ewe, ingasetyenziselwa lonke uhlobo lwerobhothi, njengeKuka, Yaskawa, Fanuc, Abb, njl.

Q. Kuthiwani ngombane wesikhululo sokucoca imipu yokuwelda?

A. 24V

UMBUZO

A. 100 ~ 150 iiyunithi rhoqo ngenyanga

Umbuzo. Ngaba isikhululo setotshi sicocekile sisetyenziselwa ukusika iingcingo?

A. Ewe, ngomnye wemisebenzi.ingasetyenziselwa ukusika ucingo, ukutshiza ioli kunye nokucoca itotshi.

Umbuzo

A. ioli echasene ne-splash, i-wire cutter kunye ne-ream.