Sijonge Ngezenzo!

Ukusebenza kweWelding

Kuphela ukusebenza Okulungileyo kwe-welding yinjongo yethu

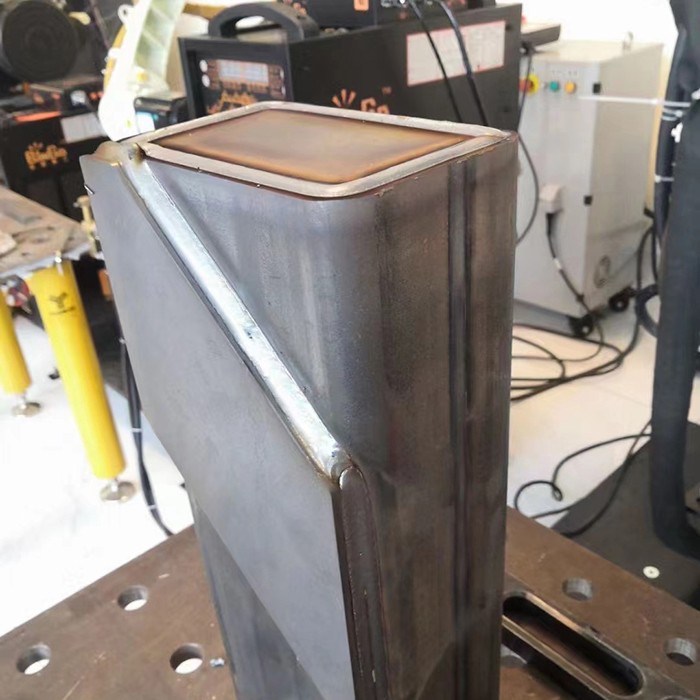

Umzekelo odumileyo ulandelayo

Umthombo wamandla we-MIG, iManuwali kunye nemodeli yeRobhothi, Xhasa iprotocal yonxibelelwano eyahlukileyo

Pulse MIG/MAG 350/500IX

Umatshini wokuwelda okhuselweyo weMono-pulse MIG/MAG Gas Shielded

I-MIG/MAG Constant Voltage

I-MIG/MAG impulse Imisebenzi:

Impulse MIG/MAG, jikelele MIG/MAG.

Ishishini lesicelo:

Uloliwe ohamba ngesantya esiphezulu, inqanawa yoxinzelelo, ukupakishwa kwakhona kwemoto, i-yacht, i-high-voltagetshintsha kunye nokwahlula indawo.

Iimbonakalo:

◆CPU + DSP epheleleyo yedijithali inkqubo yolawulo oluchanekileyo oluchanekileyo ilawula ngokuchanekileyo i-waveform kwaye iqonda ukuguqulwa okugqibeleleyo kwe-droplet enye nge-pulse, kunye ne-arc ezinzileyo ye-welding, i-spatter ephantsi, imbonakalo enhle ye-weld kunye nomgangatho ophezulu we-welding;

◆I-database ye-welding ye-welding eyakhelwe-ngaphakathi ibandakanya imilinganiselo echanekileyo yolawulo lwe-welding waveform, i-parameters kwinkqubo ye-welding kunye ne-arc striking and suppression parameters.Kukulungele ukuhlengahlengisa iiparamitha kwaye uthelekise ngokuzenzekelayo kunye neeparamitha ezifanelekileyo;

◆ Ulungelelwaniso oludibeneyo / olwahlukileyo lulungele ukuhlangabezana nemikhwa yokusebenzisa eyahlukeneyo;

◆Iindlela zokusebenza ezine zamanyathelo amabini, amanyathelo amane, amanqanaba amane akhethekileyo kunye nokuwelda kwamabala.Kwi welding enkuluUkucaciswa kwemithungo emide ye-welding, amanyathelo amane okanye umsebenzi okhethekileyo wamanyathelo amane anciphisa amandla okusebenza kwee-welders.kunye nokuphucula umgangatho we-welding joint;

◆Ikhawulelana ngokukhawuleza neemfuno zabasebenzisi malunga nenkqubo ye-welding ekhethekileyo.Ubuchwephesha obupheleleyo bolawulo lwedijithali bunokuhlangabezana ngokulula neemfuno ezikhethekileyo ngokuguqula nokuphucula isoftware, ngaphandle kokuguqula ihardware;

IiParameters zobuGcisa

| Umzekelo | Pulse MIG-350IX | Pulse MIG-500IX |

| Ilinganiswe igalelo lombane/ukuphindaphinda | Isigaba sesithathu380V (+/-) 10% 50Hz | |

| Umthamo wongeniso ulinganisiwe (KVA) | 17.1 | 27.6 |

| Igalelo langoku (A) | 26 | 42 |

| Ixabiso lombane wemveliso (V) | 31.5 | 39 |

| Uzinzo lomthwalo olinganiselweyo (%) | I-100 | I-100 |

| I-voltage ephuma ngaphandle komthwalo (V) | 85 | 85 |

| Uluhlu lwangoku lwemveliso (A) | 20~350 | 20~500 |

| Uluhlu lwamandla ombane ophumayo (V) | 14-40 | 14~50 |

| Idayamitha yocingo lokuwelda (mm) | 0.8, 1.0, 1.2 | 0.8, 1.0, 1.2, 1.6 |

| Uhlobo lwentambo yokuwelda | Iimpawu ze-Pulse Solid carbon steel / carbon steel core wekhemikhali, intsimbi eqinileyo eqinileyo / intsimbi engaxutywanga kunye nombindi wekhemikhali, ubhedu kunye nealloyi yobhedu. | |

| Amandla ombane ahlala ehleli uphawu lwe-CO2 yentsimbi, intsimbi yekhabhoni, intsimbi yekhabhoni, intsimbi yekhabhoni enemichiza engundoqo yentsimbi eqinileyo/engenasici engundoqo wekhemikhali, ubhedu kunye nengxubevange yobhedu. | ||

| Uhlobo lokutyisa ucingo | Tyhala/Thala-tsala | |

| Ukuhamba kwerhasi (L/min) | 15-20 | |

| Imo yokupholisa | Ukupholisa amanzi / Ukupholisa umoya | |

| Ibakala lokukhusela iqokobhe | IP21S | |

| Ibakala le-insulation | H/B | |

Pulse MIG/MAG350/500II

Umatshini wokuwelda wekhaka legesi oguqulwe kabini we-MIG/MAG

I-MMA CAC-A MIG/MAG

Manual mental Gouging Impulse

welding arc

MIG/MAG TIG

Constant Constant

amandla ombane yangoku DC/AC

Imisebenzi:

Impulse MIG/MAG, jikelele MIG/MAG, manual metal-arc welding, ukuphakamisa i-arc ebetha i-TIG kunye ne-gouging.

Ishishini lesicelo:

Uloliwe ohamba ngesantya esiphezulu, inqanawa yoxinzelelo, ukupakishwa kwakhona kwemoto, i-yacht, iswitshi enevoltage ephezulu kunye nokwahlulwa kwesithuba.

Iimbonakalo:

◆CPU + DSP epheleleyo yedijithali inkqubo yolawulo oluchanekileyo oluchanekileyo ilawula ngokuchanekileyo i-waveform kwaye iqonda ukuguqulwa okugqibeleleyo kwe-droplet enye nge-pulse, kunye ne-arc ezinzileyo ye-welding, i-spatter ephantsi, imbonakalo enhle ye-weld kunye nomgangatho ophezulu we-welding;

◆I-database ye-welding ye-welding eyakhelwe-ngaphakathi ibandakanya imilinganiselo echanekileyo yolawulo lwe-welding waveform, i-parameters kwinkqubo ye-welding kunye ne-arc striking and suppression parameters.Kukulungele ukuhlengahlengisa iiparamitha kwaye uthelekise ngokuzenzekelayo kunye neeparamitha ezifanelekileyo;

◆ I-CPU epheleleyo yedijithali ilawula inkqubo yokulawula ukuchaneka okuphezulu kokutya kocingo kunye ne-two-drive kunye nesixhobo sokulawula idijithali esipheleleyo socingo kunye ne-encoder iqinisekisa ukutyisa ucingo oluzinzileyo xa umthwalo wokutshintshwa kocingo okanye umbane womnatha. iyaguquguquka kwinkqubo ye-welding;

◆ Ulungelelwaniso oludibeneyo / olwahlukileyo lulungele ukuhlangabezana nemikhwa yokusebenzisa eyahlukeneyo;

◆ Ineendlela zokusebenza ezine zamanyathelo amabini, amanyathelo amane, amanqanaba amane akhethekileyo kunye ne-spot welding.Kwi-welding ye-welding enkulu ye-welding seams emide, inyathelo elinesine okanye umsebenzi okhethekileyo wamanyathelo amane anciphisa amandla okusebenza kwee-welders kunye nokuphucula umgangatho we-welding joint;

◆Ikhawulelana ngokukhawuleza neemfuno zabasebenzisi malunga nenkqubo ye-welding ekhethekileyo.Ubuchwephesha obupheleleyo bolawulo lwedijithali bunokuhlangabezana ngokulula neemfuno ezikhethekileyo ngokuguqula nokuphucula isoftware, ngaphandle kokuguqula ihardware;

IiParameters zobuGcisa

| Umzekelo | Pulse MIG-350II | Pulse MIG-500II |

| Ilinganiswe igalelo lombane/ukuphindaphinda | Isigaba sesithathu380V (+/-) 10% 50Hz | |

| Umthamo wongeniso ulinganisiwe (KVA) | 17.1 | 27.6 |

| Igalelo langoku (A) | 26 | 42 |

| Ixabiso lombane wemveliso (V) | 31.5 | 39 |

| Uzinzo lomthwalo olinganiselweyo (%) | 60 | 60 |

| I-voltage ephuma ngaphandle komthwalo (V) | 85 | 85 |

| Uluhlu lwangoku lwemveliso (A) | 20~350 | 20~500 |

| Uluhlu lwamandla ombane ophumayo (V) | 14-40 | 14~50 |

| Idayamitha yocingo lokuwelda (mm) | 0.8, 1.0, 1.2 | 0.8, 1.0, 1.2, 1.6, 2.0 |

| Uhlobo lwentambo yokuwelda | Iimpawu zePulse Intsimbi yekhabhoni eqinileyo / intsimbi yekhabhoni enemichiza engundoqo, intsimbi eqinileyo / engenanto enemichiza engundoqo iAl-Mg ingxubevange, ialuminium ecocekileyo kunye neAl-Si ingxubevange, ubhedu kunye nealloyi yobhedu. | |

| Umbane othe rhoqo uphawu lwentsimbi ye-CO2, intsimbi yekhabhoni, intsimbi yekhabhoni enondoqo wekhemikhali | ||

| Uhlobo lokutyisa ucingo | Tyhala/Thala-tsala | |

| Ukuhamba kwerhasi (L/min) | 15-20 | |

| Imo yokupholisa | Ukupholisa amanzi / Ukupholisa umoya | |

| Ibakala lokukhusela iqokobhe | IP21S | |

| Ibakala le-insulation | H/B | |

MIG -M350/500/630

Umatshini wokuwelda okhuselwe yigesi ye-CO2

MIG/MAG

rhoqo

I-Voltage

Imisebenzi:

I-MIG/MAG yegesi ekhuselwe umatshini wokuwelda, i-manual metal-arc welding.

Ishishini lesicelo:

Ukwakhiwa kweenqanawa, isitya, oomatshini bobunjineli, ishishini lepetrochemical kunye nesakhiwo sentsimbi.

Iimbonakalo:

◆ Ine-arc ezinzileyo ye-welding, i-spatter esezantsi, inkangeleko entle ye-weld kunye nomgangatho ophezulu we-welding;Ineeparamitha ezichanekileyo zolawulo lwe-welding waveform, iiparamitha kwinkqubo ye-welding kunye ne-arc ebethayo kunye neeparamitha zokucinezela.Kukulungele ukuhlengahlengisa iiparamitha kwaye uthelekise ngokuzenzekelayo kunye neeparamitha ezifanelekileyo;

◆Abasebenzisi banokuzigcina.iiparamitha ezichaziweyo zenkqubo ye-welding kunye nokulawula inkqubo ye-welding kunye nokubonelela ngokulula kwi-welding ehlukeneyo yesikhululo esifanayo ngokukhumbula kunye nokusebenzisa iiparitha zenkqubo ye-welding;

Iiparamitha zokufundisa

| Umzekelo | MIG- 350M | MIG- 500M | MIG-630M |

| Ilinganiswe igalelo lombane / rhoqo | Isigaba sesithathu380V (+/-) 10% 50Hz | ||

| Amandla ongeniso alinganisiwe (KVA) | 16.5 | 27.6 | 36 |

| Igalelo langoku (A) | 25 | 42 | 54 |

| Ixabiso lombane wemveliso (V) | 31.5 | 39 | 44 |

| Uzinzo lomthwalo olinganiselweyo (%) | I-100 | I-100 | 60 |

| I-voltage ephumayo engenamthwalo (V) | 68 | 68 | 86 |

| Uluhlu lwangoku lwemveliso (A) | 60~350 | 60~500 | 60~630 |

| Uluhlu lwamandla ombane ophumayo (V) | 15-40 | 15~50 | 15~50 |

| Idayamitha yocingo lokuwelda (mm) | 0.8, 1.0, 1.2 | 1.0, 1.2, 1.6 | 1.0, 1.2, 1.6 |

| Uhlobo lokutyisa ucingo | Dudula | ||

| Imowudi yokupholisa umpu we-welding | Ukupholisa amanzi / Ukupholisa umoya | ||

| Ibakala lokukhusela iqokobhe | IP21S | ||

| Ibakala le-insulation | H/B | ||

I-ARC315/400/500/630/1000/1250/1500

Iwelder ye-arc eguqulweyo ye-DC

MMA

Ingqondo yezandla

welding arc

I-CAC-A

Gouging

Imisebenzi:

Manual metal-arc welding.

Iintsimbi ezidityaniswayo:

Intsimbi yekhabhoni kunye nentsimbi.

Iimbonakalo:

◆Iphaneli yokulawula inoyilo olufanelekileyo kunye nomboniso wedijithali, kunye ne

i-welding yangoku inokulungiswa ngokuchanekileyo;

◆I-arc ebethayo yangoku inokulungiswa ngokwahlukileyo, kwaye ine-

ukusebenza kakuhle kwe-arc;

◆I-arc thrust current ingalungiswa ngokwahlukileyo;

◆ Inemisebenzi yokukhusela ukhuseleko njengokhuseleko lobushushu,

ukhuseleko lwangoku kunye nokhuseleko lwesiphaluka esifutshane.

IParameter yokufundisa

| Umzekelo | ARC-315 | ARC-400 | ARC-500 | ARC-630 | ARC-1000 | ARC-1500 |

| Ilinganiswe igalelo lombane / frequency | Isigaba sesithathu380V (+/-) 10% 50Hz | |||||

| Umthamo wongeniso ulinganisiwe (KVA) | 11.2 | 18.4 | 25 | 31.6 | 55 | 89 |

| Igalelo langoku (A) | 17 | 28 | 38 | 52 | 83 | 140 |

| Ixabiso lombane wemveliso (V) | 32.6 | 36 | 40 | 44 | 60 | 70 |

| Uzinzo lomthwalo olinganiselweyo (%) | 60 | |||||

| I-voltage ephuma ngaphandle komthwalo (V) | 70 | 70 | 81 | 86 | 86 | 86 |

| Uluhlu lwangoku lwemveliso (A) | 30~315 | 40-400 | 50~500 | 63-630 | 63-1000 | 63-1500 |

| Ibakala lokukhusela iqokobhe | IP21S | |||||

| Ibakala le-insulation | H/B | |||||

| imo yokupholisa | Ukupholisa umoya | |||||

SIYACALA

IBHAYINGOephanda rhoqo kwaye ayiphuhliseitekhnoloji ye-welding ekrelekrelevumela izixhobo zokuwelda ngaphezuluukuya kwihlabathi

SIYATHANDA

Ngoku iye yachatshazelwa kwaye yathandwangamazwe amaninzikwilixa elizayo

SIYAMANGALISA

Siza kutyala imali eninzi kwizibonelelor okuqhubekayo & d kunye nemvelisoBheka phambiliungaze uyeke