TIG welding Robot

Intshayelelo yeMveliso

I-GTAW iqhele ukusetyenziselwa ukuwelda amacandelo abhityileyo entsimbi engatyiwayo kunye neentsimbi ezingezizo ezoni ezifana ne-aluminiyam, i-magnesium, kunye nengxubevange yobhedu. Inkqubo inika umqhubi ulawulo olukhulu phezu kwe-weld kuneenkqubo ezikhuphisanayo ezifana ne-shielded metal arc welding kunye ne-gas metal arc welding, evumela ukuba ukuqina, umgangatho ophezulu we-welds. Nangona kunjalo, i-GTAW intsonkothe ngakumbi kwaye inzima ukuyiqonda, kwaye ngaphezu koko, iyacotha kakhulu kunezinye iindlela zokuwelda. Inkqubo ehambelanayo, i-plasma arc welding, isebenzisa itotshi ye-welding eyahlukileyo ukwenza i-arc ye-welding egxininisekileyo kwaye ngenxa yoko ihlala izenzekelayo.

I-Yunhua isebenzisa amanyathelo okuthintela okhethekileyo ngexesha le-TIG ye-welding, kwaye kuya kubakho incwadana ekhethekileyo yomqhubi, kuphela ukuba umqhubi unokulandela i-manual, kwaye asebenzise amaxesha amaninzi, inokulawulwa ngokukhawuleza.

PRODUCT PARAMETER & IINKCUKACHA

| Umzekelo | I-WSM-315R | I-WSM-400R | I-WSM-500R | |

| Ilinganiswe igalelo lombane / frequency | Isigaba sesithathu380V (+/-) 10% 50Hz | |||

| Umthamo wongeniso ulinganisiwe (KVA) | 11.2 | 17.1 | 23.7 | |

| Igalelo langoku (A) | 17 | 26 | 36 | |

| Uzinzo lomthwalo olinganiselweyo (%) | 60 | 60 | 60 | |

| I-DC kunye ne-current current | Umjikelo wokuwelda (A) | 5~315 | 5-400 | 5~500 |

| DC pulse | Incopho yangoku (A) | 5~315 | 5-400 | 5~500 |

| Isiseko sangoku (A) | 5~315 | 5-400 | 5~500 | |

| Umsebenzi wePulse (%) | 1-100 | 1-100 | 1-100 | |

| I-Pulse frequency (Hz) | 0.2~20 | |||

| TIG | I-Arc iqala ngoku (A) | 10-160 | 10-160 | 10-160 |

| I-arc yokumisa okwangoku (A) | 5~315 | 5-400 | 5~500 | |

| Ixesha lokunyuka kwangoku (S) | 0.1-10 | |||

| Ixesha lokuhla-kwangoku (S) | 0.1~15 | |||

| Ixesha lokuhamba kwangaphambili (S) | 0.1~15 | |||

| Ixesha lokuyeka ukumisa igesi (S) | 0.1-20 | |||

| Indlela yokusebenza ye-arc yokumisa yangoku | Amanyathelo amabini, Amanyathelo amane | |||

| TIG pilot arc isitayile | HF arc | |||

| I-arc yesandla yeWelding yangoku | 30~315 | 40-400 | 50~500 | |

| Imo yokupholisa | Ukupholisa amanzi | |||

| Ibakala lokukhusela iqokobhe | 1P2S | |||

| Ibakala lokugquma | H/B | |||

Isicelo

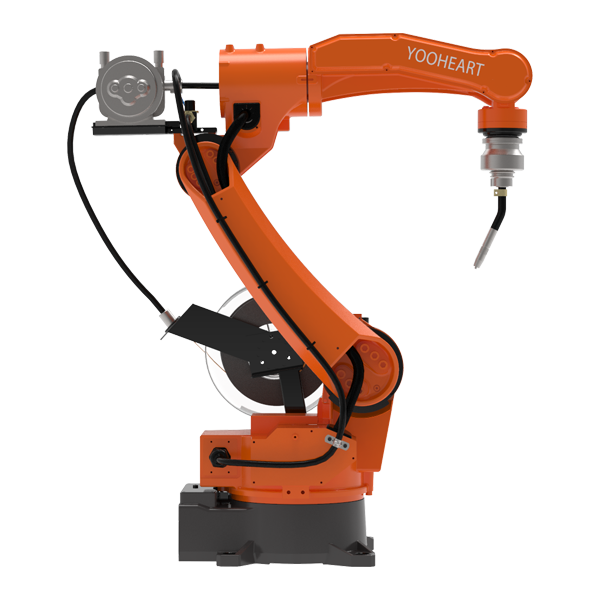

UMZO 1

Intshayelelo

Irobhothi yeTig yentsimbi yoMbane

Inkqubo ye-Pulse Tig welding ye-fish scale weld seam.

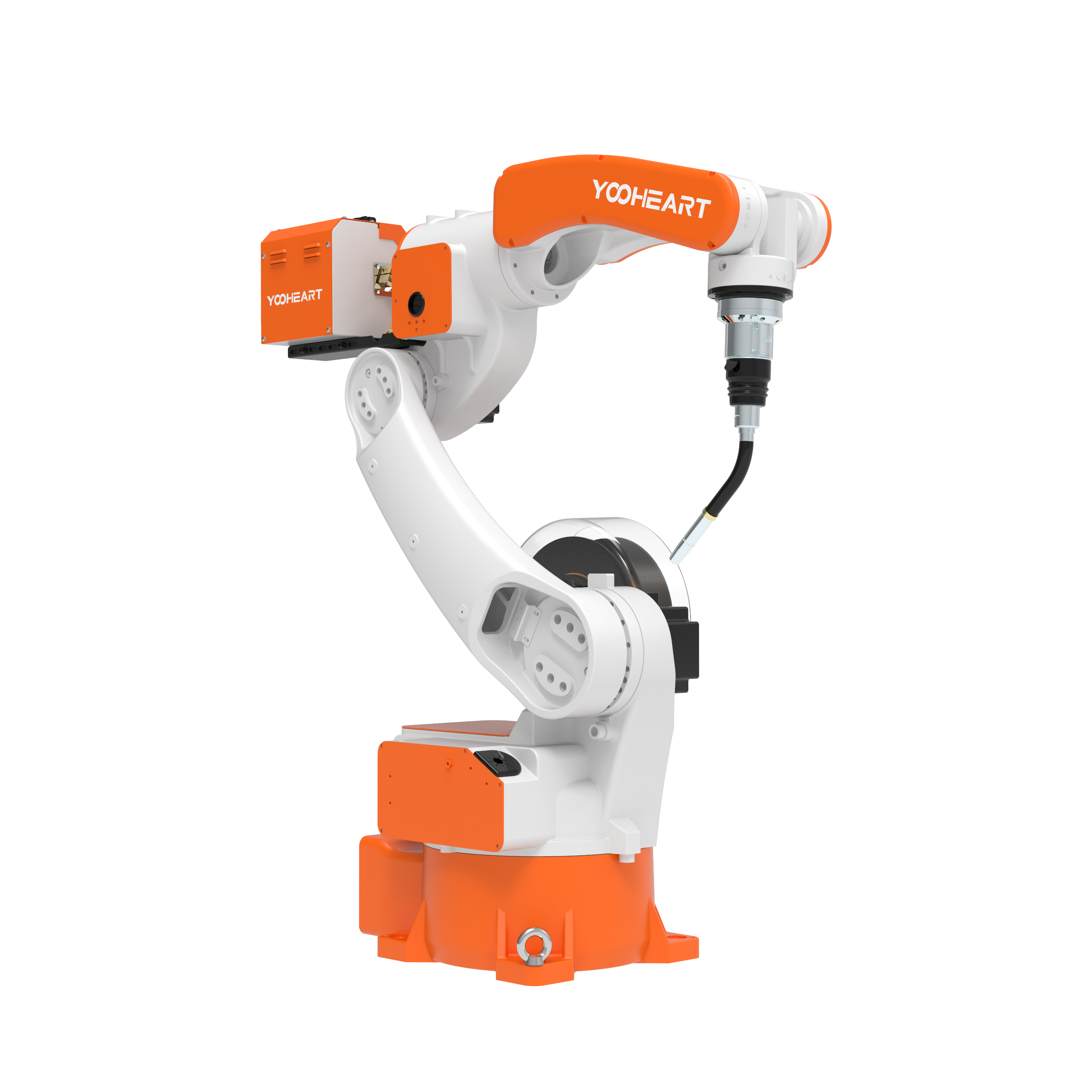

UMZO 2

Intshayelelo

I-robot ye-Tig ye-welding ye-Stainless steel

I-Tig arc welding ye-welding yesikwere yombhobho.

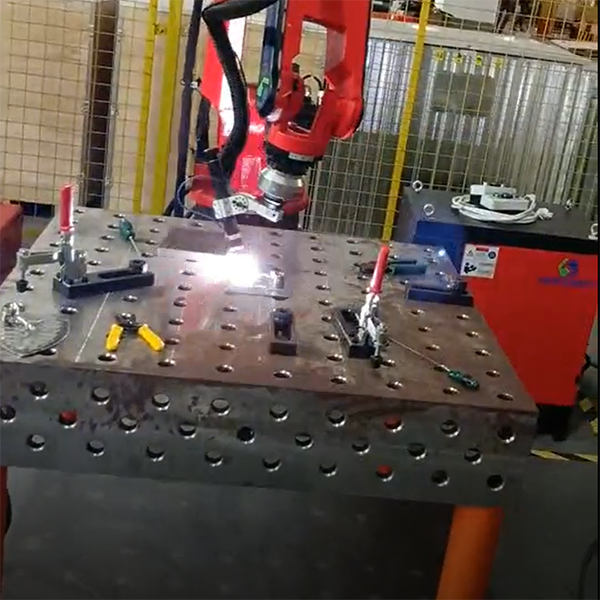

UMZO 3

Intshayelelo

Iiparamitha ze-TIG welding welder

Ukusebenza kwePulse Tig welding. Ukutyeba: 1.5mm, impazamo efanelekileyo: ± 0.2mm.

UKUNIKEZELWA NOKUTHUMELA

I-Yunhua inokubonelela abathengi ngemimiselo eyahlukeneyo yokuhanjiswa. Abathengi banokukhetha indlela yokuhambisa ngolwandle okanye ngomoya ngokokubaluleka kokungxamiseka. Iimeko zokupakisha iirobhothi ze-YOO HEART zinokuhlangabezana neemfuno zothutho lolwandle kunye nomoya. Siza kulungiselela zonke iifayile ezifana ne-PL, isatifikethi semvelaphi, i-invoyisi kunye nezinye iifayile. Kukho umsebenzi omsebenzi wakhe ophambili kukuqinisekisa ukuba yonke irobhothi inokuhanjiswa kwizibuko labathengi ngaphandle kokuphazamiseka kwiintsuku ezingama-40 zokusebenza.

Emva kwenkonzo yokuthengisa

Wonke umthengi kufuneka azi ukuba i-YOO HEART robot ilungile ngaphambi kokuba bayithenge. Emva kokuba abathengi bane-robot enye ye-YOO HEART, umsebenzi wabo uya kuba neentsuku ze-3-5 zoqeqesho lwamahhala kwi-YOO HEART factory. Kuya kuba neqela le-Wechat okanye iqela le-WhatsApp, ochwepheshe bethu abajongene nenkonzo emva kwenkonzo yokuthengisa, umbane, i-hardware, isofthiwe, njl njl. Ukuba ingxaki enye iyenzeka kabini, i-technician yethu iya kwinkampani yabathengi ukusombulula ingxaki.

FQA

Q1. Zeziphi ezona zicelo zingcono zerobhothi yeTIG welding system?

I-A.I-volume ephezulu, izicelo eziphantsi-ezihlukeneyo zifanelekile kwi-robotic welding; nangona kunjalo, ivolumu esezantsi, izicelo ezizintlobo ngeentlobo zinokusebenza kwakhona ukuba ziphunyezwe ngesixhobo esifanelekileyo. Iinkampani ziya kufuneka ziqwalasele iindleko ezongezelelweyo zezixhobo zokuqinisekisa ukuba inkqubo ye-robotic welding isenokubonelela ngembuyekezo eqinileyo kutyalo-mali lokuqala. Ngokubhekiselele kwi-TIG welding, isicelo esilungileyo ziziqwenga ezincinci kunye nentsimbi.

Q2. Yiyiphi esebenzisa ngcono? Ukuwelda kwe-HF TIG okanye Phakamisa ukuwelda kwe-TIG?

A. Eyona ndlela idumileyo kunye neyona ndlela ilungileyo kukusetyenziswa kwe-High Frequency start eyenza i-arc frequency ephezulu ekwazi ukwenza i-ionizing emoyeni kunye nokuvala umsantsa phakathi kwendawo ye-tungsten kunye nomsebenzi. Ukuqala kwe-Frequency ephezulu yindlela yokuchukumisa-ngaphantsi kwaye idala phantse ungcoliseko ngaphandle kokuba i-tungsten igqithile ilolwe okanye i-amperage ijikwe phezulu kakhulu ekuqaleni. Lolona khetho lubalaseleyo kwi-aluminium yokuwelda, kwaye ngokwenene lolona khetho olwamkelekileyo. Ngaphandle kokuba ufuna ukuwelda iAluminiyam, akuyomfuneko ukuba ube nesiqalo seFrequency ePhakamileyo, kodwa kulungile ukuba udibanise i-AC okanye i-DC ukuba unokhetho.

Q3. Ngaba i-YOO HEART TIG i-robot ye-welding ingasebenzisa isigcwalisi?

A. Ewe, singomnye wabambalwa abanokusebenzisa i-filler xa i-TIG idibanisa. Uninzi lwababoneleli kwimarike banokukuxelela ukuba iirobhothi zabo zingasetyenziselwa ukuwelda kwe-TIG, unokumbuza imibuzo efana nale: indlela yokucoca i-HF?

Q4. Indlela yokuseta umthombo wamandla xa usebenzisa i-TIG welding?

A.Umatshini wakho wokuwelda kufuneka usetelwe kwi-DCEN (i-electrode engalunganga yangoku ethe ngqo) ikwabizwa ngokuba yi-polarity ethe tye kuyo nayiphi na into ekufuneka idityaniswe ngaphandle kokuba imathiriyeli i-aluminiyam okanye i-magnesium. I-frequency ephezulu isetelwe ukuqala efunyenwe yakhiwe kule mihla kwii-inverters. Ukuhamba kweposi kufuneka kumiselwe ubuncinci imizuzwana eyi-10. Ukuba i-A/C ikhona imiselwe kulungiselelo olungagqibekanga oludibana ne-DCEN. Cwangcisa umnxibelelanisi kunye nokutshintsha kwe-amperage kwisethingi ezikude. Ukuba izinto ezifuna ukudityaniswa yi-aluminium polarity kufuneka ibekwe kwi-A / C, ibhalansi ye-A / C kufuneka ibekwe malunga ne-7 kwaye unikezelo lwamaza amaninzi kufuneka luqhubeke.

Q5. Indlela yokuseta ikhaka leGesi ngexesha lokuwelda kwe-TIG?

A. I-TIG welding isebenzisa igesi ye-inert yokukhusela indawo ye-welding ekungcoleni. Ngaloo ndlela le gesi engasebenziyo ikwachazwa njengerhasi ekhuselayo. Kuzo zonke iimeko kufuneka ibe yi-argon kwaye kungabikho enye igesi ye-inert efana neon okanye i-xenon njl njl ngakumbi ukuba i-TIG yelding kufuneka yenziwe. Kufuneka ibekwe malunga ne-15 cfh. Ukudibanisa i-aluminiyam yodwa ungasebenzisa i-50/50 indibaniselwano ye-argon kunye ne-helium.