Ishishini leemoto lithetha into enye nenguqulelo entsha, efuna ukuchaneka okungayekeleliyo, isantya, kunye nokuthembeka kwimveliso yecandelo. Phakathi kweendawo ezibalulekileyo zeemoto, iinkqubo zokukhupha-ingakumbi imibhobho yokukhupha-idlala indima ebalulekileyo ekusebenzeni kwemoto, ukulawula ukukhutshwa kunye nokunciphisa ingxolo. Njengoko abavelisi bezabalazela ukuhlangabezana nemigangatho engqongqo yomgangatho kunye neethagethi zemveliso, iirobhothi ze-welding ziye zavela njengezixhobo eziyimfuneko ekwenziweni kweenkqubo zokukhupha umoya. Eli nqaku liphonononga indlela iirobhothi zokuwelda iinkqubo, ezidityaniswe kunye nezixhobo zokumisa eziphambili ezifanaizikhundla ezijikelezayokwayeizixhobo ezenziwe ngokwezifiso, baguqula ukuveliswa kwemibhobho yokukhupha iimoto, ukuphakamisa ukusebenza kakuhle, ukungaguquguquki, kunye nomgangatho wemveliso ukuya kumanqanaba angazange abonwe ngaphambili.

1. Ukuntsonkotha kokuVeliswa kwemibhobho yokuPhuma

Imibhobho yokukhupha iphantsi kweemeko ezinzima, kubandakanywa amaqondo obushushu aphezulu, iigesi ezidliwayo, kunye nokungcangcazela koomatshini. Ukumelana nale miceli mngeni, ngokwesiqhelo zenziwe ngentsimbi engatyiwa okanye ialuminum kwaye zifuna intsimbi engenamthungo, engenamoya kuzo zonke iijiyometri ezintsonkothileyo. Iinkqubo zemveli ze-welding manual zihlala zisokola ukugcina ukungaguquguquki kwizicelo ezinjalo, ezikhokelela kwiziphene ezifana ne-porosity, ukudibanisa okungaphelelanga, okanye ukuphazamiseka.

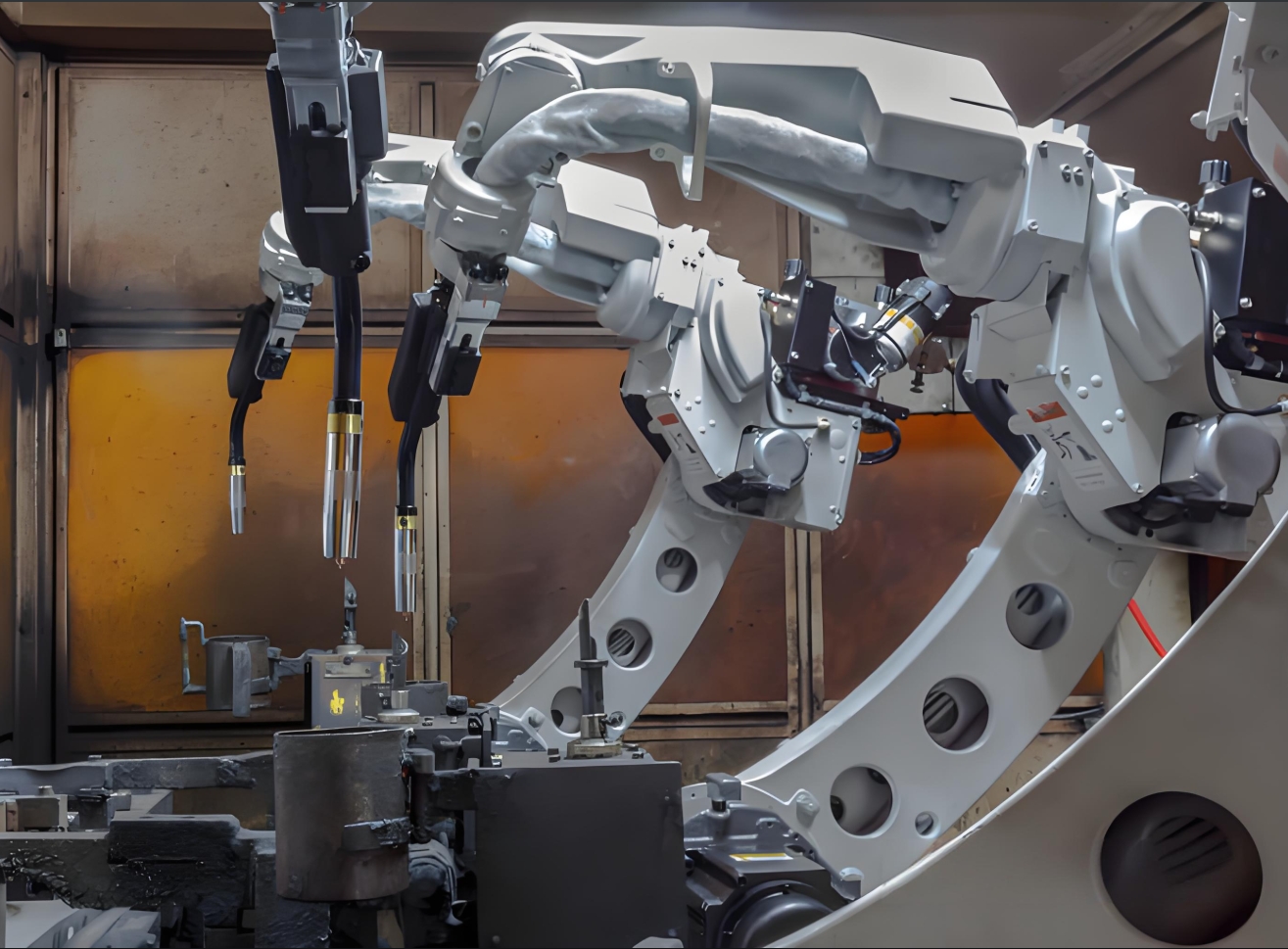

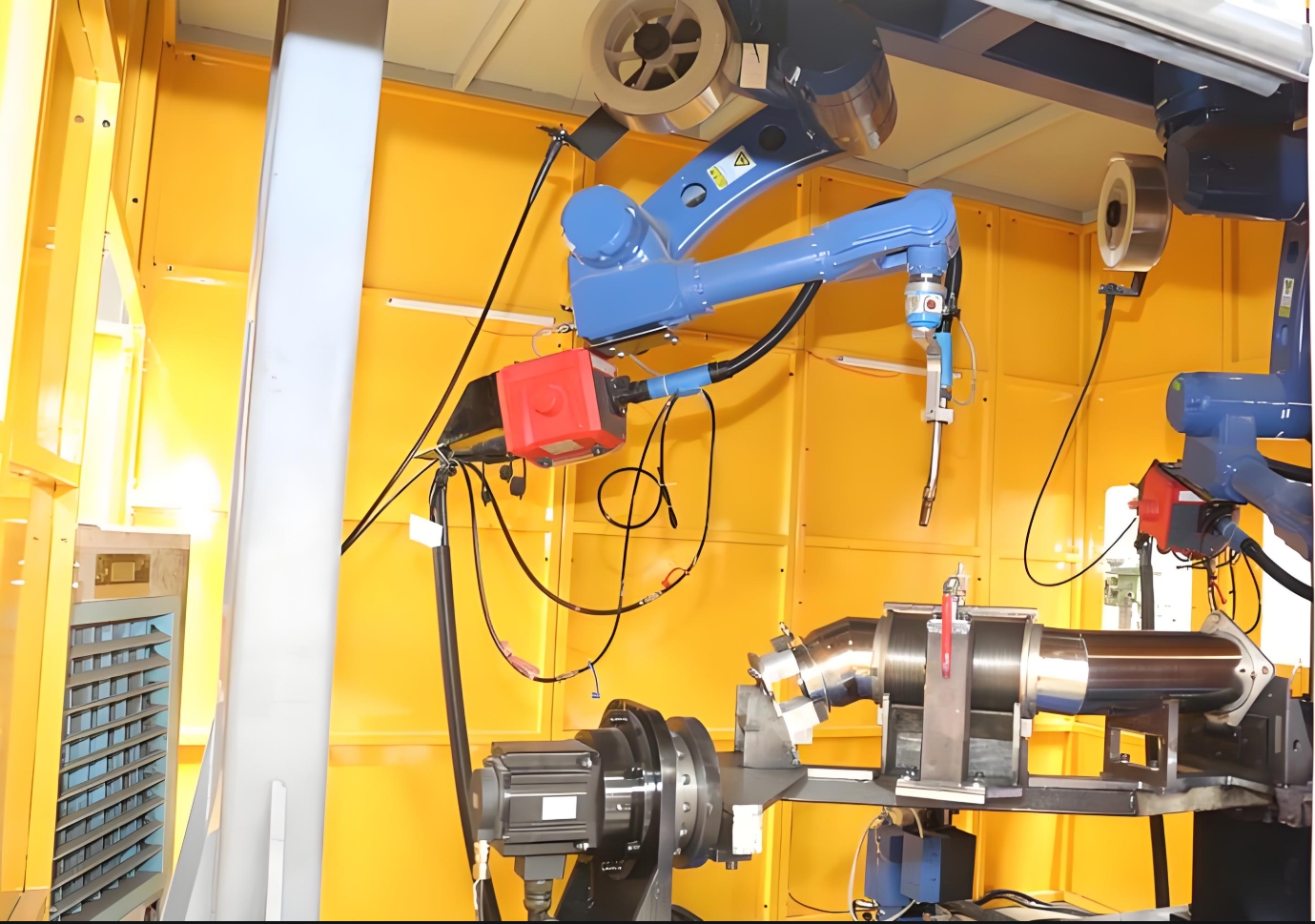

Iirobhothi zokuwelda, nangona kunjalo, ziyagqwesa ekuphatheni ezi ngxaki. Ukuxhotyiswa nge-multi-axis articulation kunye ne-synced kunye neenkqubo zokubeka ezichanekileyo, zihambisa ii-welds ezingenasiphako kwiindawo ezigobileyo, ii-flanges, kunye namalungu-okubalulekileyo ekuqinisekiseni ukunyaniseka kwenkqubo yokukhupha.

2. I-Robotic Welding in Action: Izicelo eziphambili zeMibhobho yokukhupha

2.1 I-Tube-to-Flange kunye ne-Tube-to-Muffler Welding

Iinkqubo zokukhupha zibandakanya amacandelo amaninzi, kubandakanywa imibhobho, abaguquli be-catalytic, i-resonators, kunye ne-mufflers. Iinkqubo zerobhothi ze-welding zenza ukudibanisa kweetyhubhu kwiiflange okanye izindlu ze-muffler, ziqinisekisa ukungena okufanayo kunye nokunciphisa iindawo ezichaphazelekayo ukushisa (HAZ). Umzekelo, aI-6-axis echazwe kwirobhothiinokuhamba ijikeleze isangqa sombhobho, igcine ii-engile zetotshi ezizezona zilungileyo kunye nezantya zohambo nakwimigangatho ekhondweni.

2.2 I-Laser Welding ye-Thin-Walled Components

Imibhobho yale mihla yokukhupha isoloko ineendonga ezicekethekileyo zokuyila ukunciphisa ubunzima ngelixa igcina amandla. Iirobhothi zokuwelda ngeLaser, ezinoxinano lwamandla aphezulu kunye ne-weld seams emxinwa, zithintela ukulwa kunye nokugcina iipropathi zezinto eziphathekayo. Oku kunenzuzo ngakumbi kwiinkqubo zokukhupha insimbi engenasici, apho ukuchaneka kubaluleke kakhulu.

2.3 Ii-Multi-Pass Welding ye-Thick Joints

Kwiinkqubo zokukhupha izinto ezinzima kwiimoto zorhwebo, iinkqubo ze-robotic gas metal arc welding (GMAW) zenza ii-welds ezininzi ezidlulayo ukwakha amajoyina aqinileyo phakathi kwemibhobho enodonga olungqingqwa kunye nezibiyeli. Ii-algorithms ze-welding eziguquguqukayo zilungelelanisa iiparamitha ngexesha langempela ukulungiselela ukwahluka kwezinto.

3. Ukuphucula ukuguquguquka kunye neRotary Tilt Positioners

Ukusebenza kakuhle kweeseli zerobhothi kuxhomekeke kulungelelwaniso olungenamthungo phakathi kwerobhothi kunye nomsebenzi.Izikhundla ezijikelezayo zokuthambekazibalulekile kule nkqubo, ivumela ukujikeleza kwe-360-degree kunye nokuthambeka kwemibhobho yokukhupha ngexesha le-welding. Izibonelelo ziquka:

- UkuFikelela ngokuDibeneyo okuLungileyo: I-positioner iphinda ilungelelanise umbhobho ukuze ibonise i-weld seam kwi-flat okanye indawo ethe tye, yenza lula inkqubo yerobhothi kunye nokunciphisa amaxesha okujikeleza.

- Ukubekwa ngokutsha okuNcitshisiweyo: Ngokuhlengahlengisa ngokuguquguqukayo i-workpiece, i-robot inokugqiba ii-welds ezininzi kwi-setup enye, ukunciphisa ixesha elingasebenziyo.

- Ukuphuculwa kwe-Ergonomics: Abaqhubi balayisha / bakhuphe amacandelo ngelixa i-robot i-welds, ukwandisa i-output.

Umzekelo, isitishi esinezitishi ezimbini sivumela umbhobho omnye ukuba udityaniswe ngelixa olandelayo ulayishiwe, ukuphumeza imveliso ekufutshane eqhubekayo.

4. Ukulungiswa okuchanekileyo: I-Backbone of Consistency

Customizedizixhobo zokuweldazibalulekile ekubambeni amacandelo e-exhaust ngolungelelwaniso oluchanekileyo ngexesha le-robotic welding. Iingqwalasela eziphambili zoyilo ziquka:

- IiNdlela zokuBamba: Izibophelelo zomoya okanye zehydraulic zikhusela imibhobho, iiflange, kunye nezibiyeli ngaphandle kokumosha indawo.

- Ukumodareyitha: Izixhobo ezikhawulezayo zokutshintsha zithatha i-diameter ehlukeneyo yombhobho okanye ulungelelwaniso, olulungele ukuveliswa kwemodeli edibeneyo.

- Ulawulo lweThermal: Izilungiso ezenziwe ngezinto ezikwazi ukumelana nobushushu zimelana nokuvezwa ixesha elide kwi-welding arcs.

Izilungiso ezikwinqanaba eliphezulu zidibanisa abenzi boluvo ukuqinisekisa ukubekwa kwecandelo phambi kokuba kuqale ukuwelda, ukuphelisa iziphene ezingahambi kakuhle.

5. Ukulinganisa iinzuzo zokuSebenza ngokuSebenzayo

Ukwamkelwa kweenkqubo zokuwelda iirobhothi kwimveliso yemibhobho yokukhupha ikhupha uphuculo olunokulinganiswa:

- UkuNcitshiswa kwexesha lomjikelo: I-robotic MIG welder inokugqiba i-weld circumferential kwimizuzwana ye-60, xa kuthelekiswa nemizuzwana ye-180 + ye-welding manual.

- Ixesha eliPhakamileyo: Iirobhothi zisebenza nge-24/7 kunye nexesha elincinci lokunciphisa, ukunyusa umkhiqizo wonyaka nge-30-50%.

- Ukugcinwa kwezinto eziphathekayo: Ukulawulwa kweparameter echanekileyo kunciphisa i-spatter kunye nokusebenza kwakhona, ukunciphisa iindleko ezisetyenziswayo nge-15-20%.

Ngokomzekelo, umthengisi weemoto we-Tier-1 ubike aUkunyuka kwe-40% kwimvelisoemva kokuthumela iiseli zerobhothi ezineendawo ezilungelelanisiweyo zokuhlanganisa i-exhaust.

6. Ukuphakamisa umgangatho kwiMigangatho yeeMoto

I-welding yerobhothi iqinisekisa ukuthotyelwa kwemigangatho yemigangatho yemoto efana ne-IATF 16949:

- Ukuphindaphinda: Iirobhothi ziphindaphinda iindlela ze-weld kunye ± 0.1 mm ngokuchanekileyo, ukuphelisa ukuhluka kwabantu.

- Ukufunyanwa kwesiphako: Iinkqubo zombono ezidibeneyo okanye i-arc monitoring sensors ibona izitenxo phakathi kwenkqubo, ibangela ulungiso olukhawulezileyo.

- Amaxwebhu: Iisistim ezizenzekelayo zivelisa iilogi ze-weld ezinokulandeleka, zibaluleke kakhulu kuphicotho kunye nokukhumbula.

Ukuhlolwa kwe-post-weld kubonisa ukuba iinkqubo zerobhothi zinciphisa i-porosity kunye ne-crack rates ngaphezu kwe-90% xa kuthelekiswa neendlela zezandla.

7. Uzinzo kunye neeNdlela zekamva

Abavelisi beemoto bayanda ukubeka phambili ukuzinza. I-welding yerobhothi ixhasa olu tshintsho ngokuthi:

- Ukunciphisa ukusetyenziswa kwamandla: Ixesha elisebenzayo le-arc kunye neendlela ezishukumayo eziphuculweyo zokusetyenziswa kwamandla aphantsi.

- Ukunciphisa iNkunkuma: Amazinga aphezulu okuphumelela kokuqala anciphisa i-scrap.

- Ukunika amandla ukuKhanya: Ukuchaneka kwe-welding kunceda ukusetyenziswa kwezinto eziphambili, ezincinci ngaphandle kokunciphisa ukuqina.

Ukujonga phambili,Iirobhothi zokuwelda eziqhutywa yi-AIiya kunyusela ukufundwa komatshini ukuzilungiselela iiparamitha zezixhobo ezitsha, ngelixaiirobhothi ezisebenzisanayo (cobots)iya kunceda abaqhubi kwimveliso yeebhetshi ezincinci.

Ukuqukumbela

Kwinqanaba eliphezulu lokwenziwa kwenkqubo yokukhupha iimoto, iirobhothi ze-welding-zandiswe ziindawo ezikrelekrele kunye nezixhobo-zimela incopho yobunjineli obuchanekileyo. Ngokwenza ngokuzenzekelayo imisebenzi ye-welding enzima, ezi nkqubo zixhobisa abavelisi ukuba bafezekise amaxesha omjikelezo okhawulezayo, umgangatho ongenakulinganiswa, kunye nemveliso enokunyuka. Njengoko imimiselo yokukhupha umbhobho iqina kunye noyilo lwezithuthi luvela, itekhnoloji yerobhothi yokuwelda iya kuhlala ilitye lembombo lezinto ezintsha, iqhubela ishishini leemoto lisingise kwikamva elikrelekrele nelicocekileyo.

Kubenzi beerobhothi zoshishino, ukugxininisa obu buchule kwizicelo zemibhobho yokukhupha ayibonisi nje ubuchule bobugcisa kodwa ibeka izisombululo zabo njengamahlakani abalulekileyo ekuqhubeleni phambili ukugqwesa kokwenziwa kweemoto.

Ixesha lokuposa: Mar-21-2025