Intshayelelo

Icandelo lokwenziwa kweemoto liya lithembela ngakumbi kwiirobhothi zemizi-mveliso ukufezekisa ukuchaneka, ukusebenza kakuhle, kunye nokungaguquguquki kwimveliso. Phakathi kwezona zicelo zibaluleke kakhulu kukudityaniswa kwezixhobo zemoto, ngakumbiiiasi(kwaziwa njengeiiasi zemotookanyeiiasi zemoto), eziyimfuneko ukuzinza kwesithuthi, ukuhanjiswa kwamandla, kunye nokuthwala umthwalo. Eli nqaku liphonononga indlela phambili ngayoiinkqubo zokuwelda iirobhothibaguqula ukuveliswa kwee-axles kunye nezinye iindawo zeemoto, ngelixa begxininisa amagama angundoqo aphezulu kuzo zombiniiinxalenye zeemotokwayeiirobhothi zokuwelding.

Icandelo loku-1: Amacandelo aPhambili kwiZithuthi ekuGxiniseni

Ukwenziwa kweemoto kubandakanya iindibano ezintsonkothileyo, kunye namacandelo alandelayo abalulekile ekusebenzeni kwesithuthi. Nazi iphezulu 5 icandelo lemoto amagama angundoqoibalulekile kule ngxoxo:

- Iasi (i-Axle yemoto/i-asi yemoto)

Ii-axles zingundoqo kwi-drivetrain yesithuthi, amavili adibanisa kunye nokuxhasa ubunzima besithuthi. I-welding echanekileyo iqinisekisa ukunyaniseka kwesakhiwo kunye nokuqina. - Iinkqubo zokunqunyanyiswa

Amacandelo afana neengalo zolawulo kunye ne-struts zifuna i-welding eyomeleleyo ukumelana noxinzelelo lwendlela. - Izixhobo zokuqhuba

Amacandelo afana nezindlu ezihlukeneyo kunye nokunyuka kokuhanjiswa kuxhomekeke kwi-welds ephezulu. - Iifreyimu zeChassis

Umqolo wesithuthi, iifreyimu ze-chassis zifuna umgangatho we-weld ongaguqukiyo wokhuseleko. - Iinkqubo zokukhupha

Iiweld ezintsonkothileyo kwii-manifolds kunye nemibhobho kufuneka zixhathise ubushushu kunye nokuhlwa.

Kwezi,ukuwelda kwe-axleivelele ngenxa yobunzima bayo bobugcisa kunye nefuthe ekusebenzeni kwesithuthi.

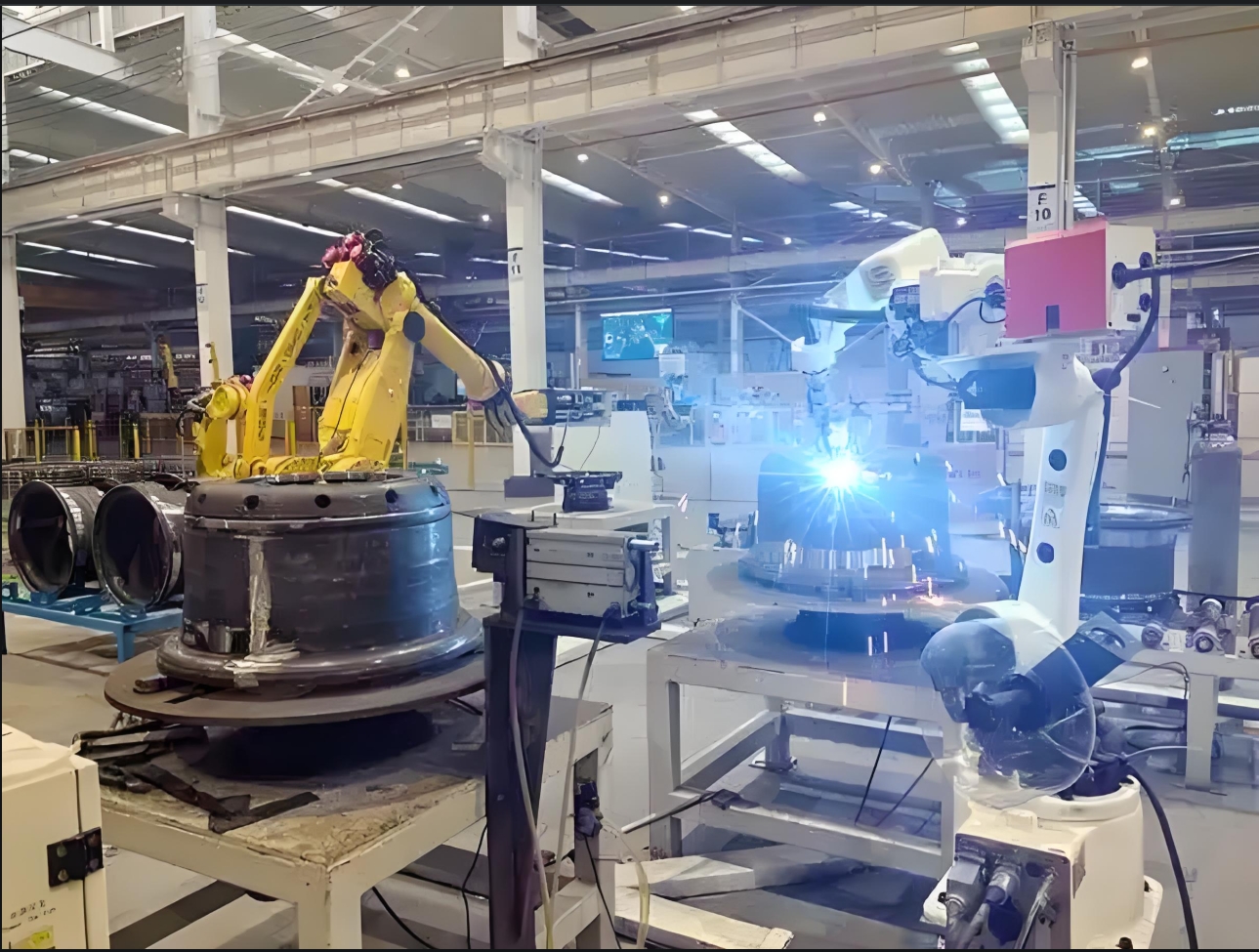

Icandelo lesi-2: Iirobhothi ze-Industrial Welding: Iteknoloji kunye neZakhono

Yangokuiinkqubo zokuwelda iirobhothiukudibanisa ubugcisa obuphambili ukuhlangabezana nemigangatho yeemoto. Ngezantsi ziphezulu 5 welding irobhothi amagama angundoqo:

- Ukuwelda okuzenzekelayo

Ukuzenzekelayo kuqinisekisa ukuphindaphinda kwaye kunciphisa impazamo yomntu kwimveliso ephezulu. - I-Arc Welding (MIG/TIG)

Kukhethwa ukwenziwa kwe-axle ngenxa yokungena okunzulu kunye nokwakheka kwamalungu aqinileyo. - Laser Welding

Isetyenziselwa imisebenzi echanekileyo ephezulu, efana nokuwelda i-axle shafts encinci ngokugqwetheka okuncinci. - Spot Welding

Ilungele ukudibanisa amashiti esinyithi adlulayo kwizinto zokunqunyanyiswa okanye ze-chassis. - Iirobhothi eziSebenzayo (iCobots)

Ukuphucula ukuguquguquka kwiindawo ezixubeneyo zemveliso, ukusebenza kunye neengcali.

Ezi teknoloji zenza ukuba abavelisi baphumelelezero-defect weldingkwizinto ezibalulekileyo njengee-asi.

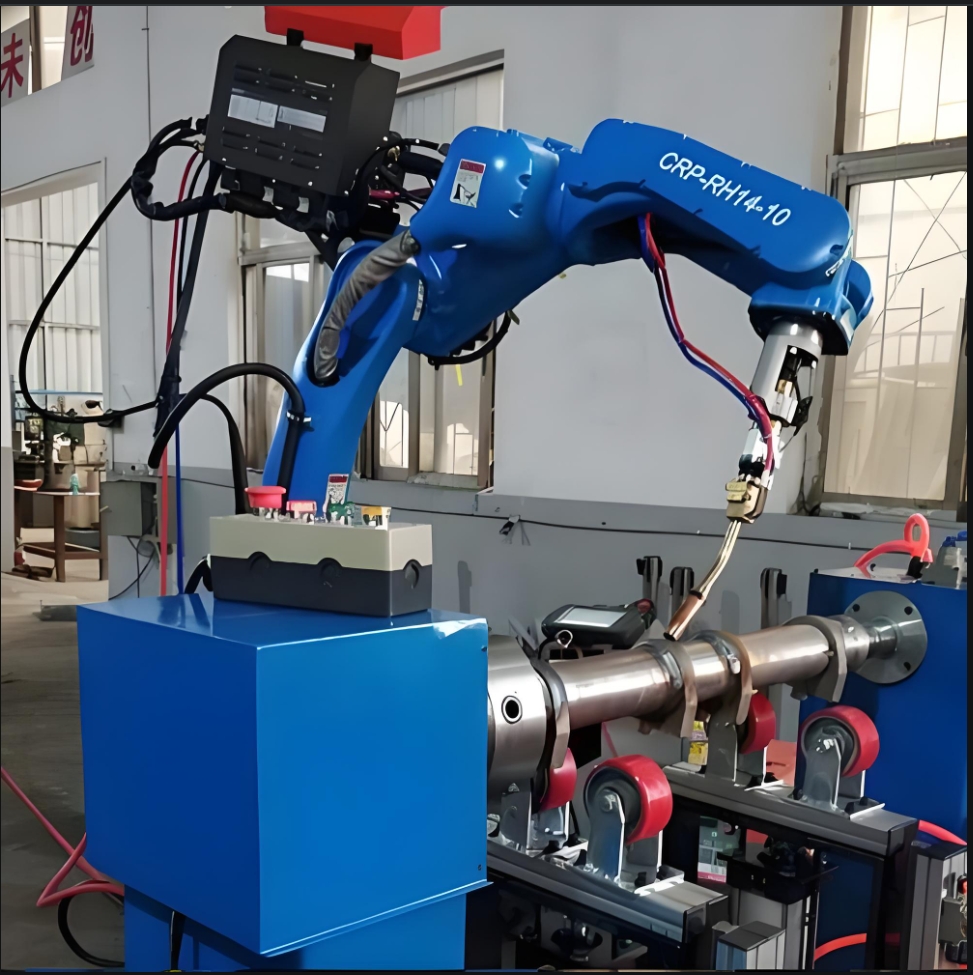

Icandelo lesi-3: Ii-axles ze-Welding ezineRobhothi ze-Industrial: Inkqubo kunye neeNzuzo

Inyathelo 1: Uyilo kunye neNkqubo

I-axle welding iqala nge-CAD/CAM yokulinganisa ukunyusa iindlela ze-weld. Iirobhothi zicwangciselwe iintshukumo ze-multi-axis, ziqinisekisa ukufikelela kwiijometri ezintsonkothileyo.

Inyathelo lesi-2: Ukulungiswa kwezinto

Ii-axles zenziwe ngentsimbi ephezulu okanye ialloys aluminiyam. Iinkqubo zerobhothi zicoceke kwangaphambili umphezulu kunye neendawo zokubambelela ukuze kuncitshiswe ukungahambi kakuhle.

Inyathelo lesi-3: Ukwenziwa kweWelding

- Arc Welding: Isetyenziselwa izindlu ezishinyeneyo ze-asi, ukuqinisekisa ubunzulu, imithungo efanayo.

- Laser Welding: Isetyenziswa kumalungu achanekileyo kuyilo lwe-asi ekhaphukhaphu.

- IiSeam Tracking Seams: Buyekeza ukungahambelani kwezinto ngexesha langempela.

Izinto eziluncedo kwi-Robotic Axle Welding:

- Amandla Ongeziweyo: Ii-welds ezihambelanayo zinciphisa amanqaku abuthathaka.

- Amaxesha oMjikelo oKhawulezayo: Iirobhothi zisebenza nge-24/7, zinyusa imveliso.

- Ugcino lweendleko: Amaxabiso asezantsi e-scrap kunye neendleko ezincitshisiweyo zabasebenzi.

- Ukhuseleko: Iphelisa ukuba sesichengeni kwiintlantsi kunye nomsi kubasebenzi.

Icandelo lesi-4: Iindlela zoShishino eziShayina i-Robotic Welding

- I-AI-Powered Quality Control

Ii-algorithms zokufunda koomatshini zihlalutya ingqibelelo ye-weld, ukuphawula iziphene ngexesha langempela. - Iimfuno zoKhaphukhaphu

Iirobhothi ziqhelana nokuweld imathiriyeli ephucukileyo njenge-aluminiyam-carbon composites kwii-axles zesithuthi sombane (EV). - Ukudityaniswa kwe-IoT

Iirobhothi ezihlakaniphile zihambisa idatha yokusebenza kwiinkqubo ezisembindini ukwenzela ukugcinwa kwangaphambili. - Uzinzo

Iinkqubo ze-welding ezisebenza ngamandla zinciphisa i-carbon footprints.

Le mikhwaiinkqubo zokuwelda iirobhothinjengento eyimfuneko kwimizi-mveliso yeemoto yanamhlanje.

Icandelo lesi-5: Imingeni kunye nezisombululo

Ngelixa iwelding yerobhothi ibonelela ngeenzuzo ezinkulu, imiceli mngeni iyaqhubeka:

- Utyalo-mali oluPhezulu oluPhezulu: Ukunciphisa i-ROI yexesha elide ukusuka kwimveliso eyandisiweyo.

- Complex Programming: Yenziwe lula ngojongano olusebenziseka lula kunye nezixhobo zokulinganisa ngaphandle kweintanethi.

- Ukuguquguquka kwezinto: Idityaniswe ngeenzwa eziguquguqukayo kunye nohlengahlengiso oluqhutywa yi-AI.

Kwi-axle welding, ukusebenzisana nabanamavaabavelisi beerobhothi zoshishinoiqinisekisa izisombululo ezilungiselelweyo.

Ukuqukumbela

I-welding yezixhobo zeemoto ezifana ne-axles ngumzekelo wamandla okuguqulaiirobhothi zoshishino. Ngokusebenzisa amandlaukuwelda okuzenzekelayo,welding arc, kwayewelding laseritekhnoloji, abavelisi bafezekisa ukuchaneka okungenakulinganiswa kunye nokusebenza kakuhle. Njengoko ishishini leemoto liguquka-ingakumbi ngokunyuka kwee-EVs-iinkqubo zokuwelda iirobhothiiyakuhlala ingundoqo ekuveliseni amacandelo asebenzayo, asebenza ngokuphezulu. Kumashishini afuna ukwenza imigca yemveliso ibe yeyanamhlanje, utyalo-mali kwiirobhothi zokuwelda ayisiyonto ikhethiweyo kodwa iyimfuneko.

Amagama angundoqo: I-Axle, i-Axle ye-Vehicle, i-Suspension Systems, i-Drivetrain Components, i-Chassis Frames; Ukuwelda okuzenzekelayo, iiNkqubo zokuWelding zeRobotic, i-Arc Welding, i-Laser Welding, i-Spot Welding.

Ixesha lokuposa: Apr-02-2025