Kukho izizathu ezininzi zokuba kutheni i-robot ye-welding itshisa i-tip yoqhagamshelwano ngexesha lenkqubo yokuvelisa i-welding. Ngokomzekelo, isiganeko somphezulu wokutshintshwa rhoqo kwe-tip yoqhagamshelwano kukuba: ukunxiba i-outlet ye-tip yoqhagamshelwano kubangela ukuba i-wire feeding ijike, kwaye umzila we-welding wangempela utshintshile, oko kukuthi, i-TCP point shift shift, iKhokelele kwi-welding defects ezifana ne-welding offset okanye ukuvuza kwe-welding.

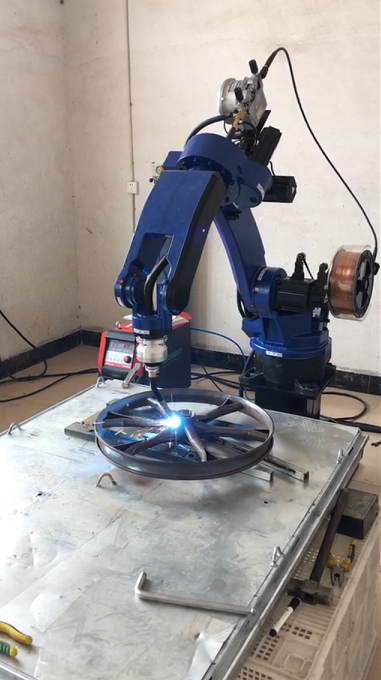

Uhlalutyo lweengxaki ezibangelwa yi-Welding Robot Burning Ingcebiso yoQhagamshelwano

1. Isizathu sokungaphumeleli kwengcebiso yoqhagamshelwano ngokwayo

Ukugqoka i-tip yoqhagamshelwano yerobhothi ye-welding ngokwayo kubangelwa ukugqoka kwi-outlet ye-tip yoqhagamshelwano ngenxa ye-friction ye-wire feeding eqhubekayo phantsi kokushisa okunyukayo kwe-tip yoqhagamshelwano. Ngethuba lokusebenza kwe-welding ye-robot ye-welding, iimpazamo zokulinganisa zihlala zenzeka kwaye zichaphazela imveliso. ukusebenza kakuhle. Ngeli xesha, kufuneka uzame ukunciphisa ubushushu bomnxeba woqhagamshelwano, kubandakanywa ukubunjwa kwesicatshulwa soqhagamshelwano kunye nokucwangciswa kwesakhiwo soqhagamshelwano. Izinto eziphathekayo zengcebiso yoqhagamshelwano: ubhedu, ubhedu obomvu, phakathi kwayo i-chromium zirconium yethusi iyona nto ibhetele; kunye nokongeza amacandelo e-ceramic kwincam yoqhagamshelwano kunokunyusa ukuxhathisa ukunxiba. Okwesithathu kukuchaneka kokucubungula kwengcebiso yoqhagamshelwano. Ngenxa yokuchaneka kwezixhobo zokucubungula okanye ezinye iingxaki, ukugqitywa komngxuma wangaphakathi kunye nokugxila kwi-tip yoqhagamshelwano ayilungile ngokwaneleyo.

2. I-arc ayizinzile, ibangela ukuba i-arc ivuthe

Esinye sezizathu zibandakanya ukuvutha kwe-arc engalunganga, i-arc engazinzanga, ukutya okungalunganga kwecingo, ukucoceka kwendawo yokusebenza, njl., kodwa ayichaphazeli ukusebenza kwencam yoqhagamshelwano ngokwayo. Ngeli xesha, ukungaphumeleli kwe-welding kuhambelana ngokumalunga neempawu zomthombo wamandla we-welding kunye nomgangatho we-welding wire. , isiphumo sokutyisa ucingo, umbhobho wokutyisa ucingo kunye noyilo lwesakhiwo sombhobho woqhagamshelwano. Xa i-welding wire kunye ne-conductive point kwi-tip yoqhagamshelwano ihlala iguquka, ubomi bayo buyisiqingatha kuphela xa i-conductive point izinzile.

3. Izizathu zokulungisa ucingo kunye nokugqiba umphezulu

I-wire welding ye-robot ye-welding ivame ukupakishwa kwi-barrel okanye ipleyiti, kwaye ibuye ibe ne-burrs okanye iimbambo, ngoko inokuchaphazela uqhagamshelwano phakathi kocingo lwe-welding kunye ne-tip yoqhagamshelwano. Xa i-robot ye-welding i-welding, i-tip yoqhagamshelwano kufuneka ibe yi-stably conductive phantsi kwesiseko Ibonelela nge-friction encinci. Ubomi bencam yoqhagamshelwano yocingo lwewelding emdaka inokuba sisinye kwisithathu kuphela sokusetyenziswa kocingo lwewelding olucocekileyo; ukugweba umgangatho wocingo lokuwelda, iqondo lokuthomalalisa uxinzelelo loxinzelelo lwentambo yokuwelda, ukusebenza yindlela ethe tye ngayo: ingxelo yovavanyo yi-50mm ukusuka phambi kwe-acrobatic welding gun nozzle, nokuba ucingo lokuwelda lunokugoba ngokuzenzekelayo, ukugoba ukuya phambili kuthetha ukuba ucingo lwe-welding luthambile kakhulu, ukugoba ngasemva kuthetha ukuba nzima kakhulu, olona cingo lubiza kakhulu; okwesibini, nokuba umbhobho wokutyisa umbhobho osuka kwi-finder yocingo ukuya kumpu we-welding ugobile uya kubangela ukuba ucingo lwe-welding lugobe. ikamber.

Ixesha lokuposa: Apr-24-2022