Okokuqala, indlela yokuvuthela yegesi yokukhusela

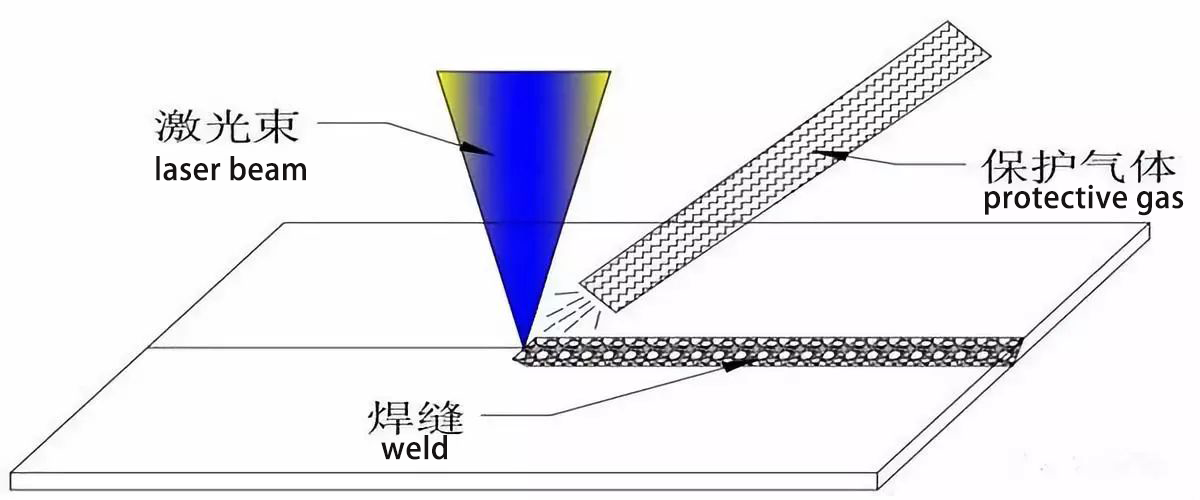

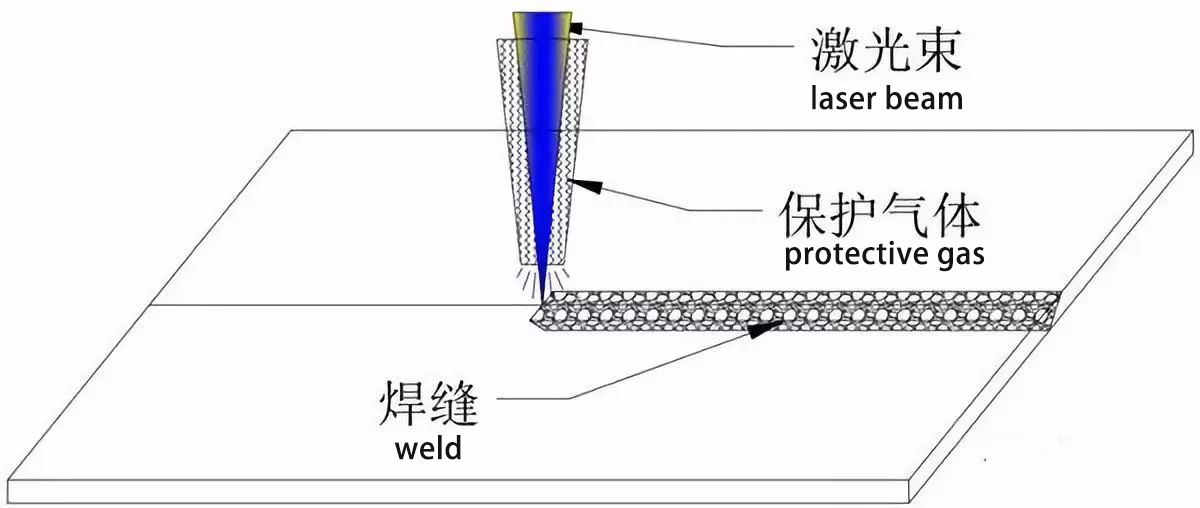

Okwangoku, kukho iindlela ezimbini eziphambili zokuvuthela igesi yokukhusela: enye i-paraxial side-blowing gas ekhuselayo, njengoko kuboniswe kuMzobo 1; Enye igesi yokukhusela i-coaxial.Ukhetho oluthile lweendlela ezimbini zokuvuthela luqwalaselwa kwiinkalo ezininzi. Ngokubanzi, kuyacetyiswa ukuba kusetyenziswe ukuvuthela ecaleni ukukhusela igesi

igesi ekhuselayo evuthela iparaxial

igesi ekhuselayo evuthela i-coaxial

igesi ekhuselayo evuthela i-coaxialEyesibini, umgaqo wokukhetha imowudi yokuvuthela kwerhasi yokhuselo

Okokuqala, kufuneka kucace ukuba into ebizwa ngokuba yi-weld "i-oxidized" kuphela igama eliqhelekileyo. Ithiyori, ibhekiselele kwindlela yokusabela kweekhemikhali phakathi kwe-weld kunye nezithako ezinobungozi emoyeni, ezikhokelela ekuwohlokeni komgangatho we-weld. Kuqhelekile ukuba i-weld metal isabele ngeoksijini, initrogen kunye nehydrogen emoyeni kwiqondo lobushushu elithile.

Ukuthintela i-weld ekubeni "i-oxidized" kukunciphisa okanye ukuphepha ukudibanisa kwezithako ezinobungozi kunye nentsimbi ye-weld kwindawo yokushisa ephezulu. Lo mbuso lobushushu eliphezulu hayi kuphela metal etyhidiweyo pool, kodwa lonke ixesha inkqubo ukususela kwixesha xa intsimbi weld inyibilika ukuqina pool metal kunye nobushushu bayo kuncitshiswe ubushushu ethile ngezantsi.

Isithathu, sithatha umzekelo.

Ngokomzekelo, i-titanium alloy welding, xa iqondo lobushushu lingaphezulu kwe-300 ℃ linokukhawuleza ukufunxa i-hydrogen, ngaphezu kwe-450 ℃ inokukhawuleza ukufunxa ioksijini, ngaphezu kwe-600 ℃ inokufunxa ngokukhawuleza i-nitrogen, ngoko ke i-titanium alloy welding seam emva kokuqina kunye nokunciphisa ubushushu ukuya kwi-300 ℃ ngaphantsi kwesi sigaba kufuneka ibe yimpembelelo yokukhusela, kungenjalo iya kuba nefuthe lokukhusela

Ukususela kule nkcazelo ingasentla akukho nzima ukuqonda, ukukhuselwa kwerhasi evuthelayo akufuneki kuphela ngexesha elifanelekileyo ukukhusela i-weld pool etyhidiweyo, kwakhona kufuneka idityaniswe kwindawo enomkhenkce yokukhusela, ngoko ngokubanzi yamkele i-paraxial eboniswe kumfanekiso we-1 icala legesi ekhuselayo, kuba le ndlela inxulumene neendlela zokukhusela ukhuseleko lwendlela yokukhusela i-coaxial ye-coaxial yendawo yokukhusela, i-2pes iyindawo yokukhusela ngakumbi.

Icala leParaxial elivuthela kwizicelo zobunjineli, ayizizo zonke iimveliso ezinokusebenzisa indlela ye-shaft esecaleni evuthela igesi yokukhusela, kwezinye iimveliso ezithile, inokusebenzisa kuphela igesi yokukhusela i-coaxial, iimfuno ezithile ezivela kwisakhiwo semveliso kunye nefom edibeneyo yokukhetha okujoliswe kuyo.

Isine, ukhetho lwendlela yokukhusela igesi yokuvuthela

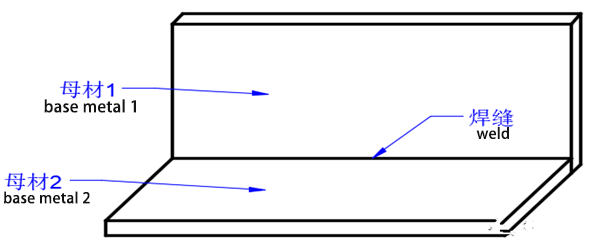

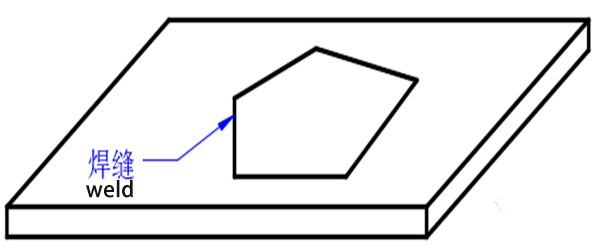

1. Iiwelds ezithe ngqo

Njengoko kubonisiwe kwi-Figure 3, imilo ye-weld yemveliso ilungile, kwaye ifom edibeneyo ingaba yinto edibeneyo ye-butt, i-lap joint, i-joint yekona engafanelekanga okanye i-welding joint joint. Kolu hlobo lwemveliso, kungcono ukwamkela icala le-sideshaft elivuthela indlela yegesi yokukhusela njengoko kubonisiwe kuMfanekiso 1.

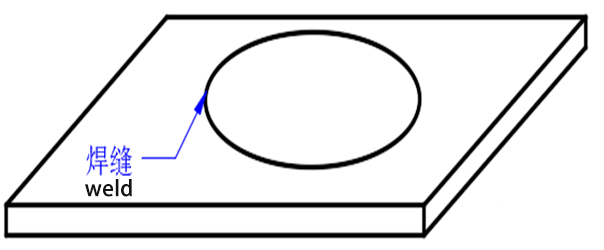

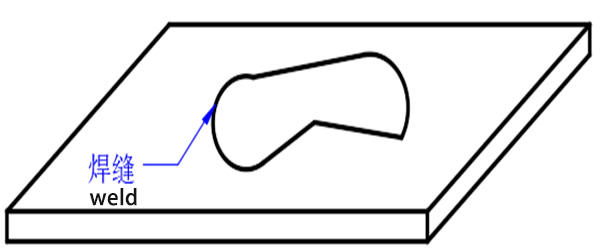

2. Umzobo ovaliweyo weld

Njengoko kubonisiwe kwi-Figure 4, imilo ye-weld yemveliso i-plane circumferential shape, i-plane shape multilateral shape, i-plane multi-segment line shape kunye nezinye iimilo ezivaliweyo. Ifom edibeneyo ingaba yi-butt joint, i-lap joint, i-welding edibeneyo kunye nokunye. Ngolu hlobo lwemveliso, kungcono ukwamkela imowudi yegesi ekhuselayo ye-coaxial eboniswe kuMfanekiso 2.

Ukukhethwa kwegesi ekhuselayo kuchaphazela ngokuthe ngqo umgangatho we-welding, ukusebenza kakuhle kunye neendleko zemveliso, kodwa ngenxa yokwahluka kwezinto zokuwelda, kwinkqubo yokuwelda yokwenene, ukhetho lwegesi ye-welding lunzima ngakumbi, ludinga uqwalaselo olubanzi lwezinto zokuwelda, indlela ye-welding, indawo ye-welding, kunye neemfuno zempembelelo ye-welding, ngokusebenzisa iimvavanyo ze-welding ukukhetha iziphumo ezifanelekileyo zokuwelda ukuphumeza ngcono iziphumo ze-welding.

Umthombo: iTekhnoloji yeWelding

Ixesha lokuposa: Sep-02-2021