Intshayelelo

Umzi-mveliso weemoto kudala unguvulindlela ekwamkeleni itekhnoloji ye-cutting-edge yokuphucula ukusebenza kakuhle, ukuchaneka, kunye nokulinganisa. Phakathi kwezinto ezibaluleke kakhulu kwisakhelo sesithuthi-i-backbone yesakhiwo eqinisekisa ukhuseleko, ukuqina, kunye nokusebenza. Njengoko iimfuno zemathiriyeli ekhaphukhaphu, ukwenza ngokwezifiso, kunye nemveliso ekhawulezileyo isanda, abavelisi baya beguqukela kwiirobhothi zamashishini ukuguqula ukwenziwa kwesakhelo. Eli nqaku liphonononga indlela iirobhothi ezilungisa ngayo ukuveliswa kwezakhelo zeemoto, ukusuka ekuphatheni izinto eziphathekayo ukuya kwi-welding kunye nokulawula umgangatho, ngelixa lijongene nemingeni kunye neendlela ezizayo kweli candelo eliguqukayo.

Icandelo loku-1: Indima ebalulekileyo yezakhelo zeZithuthi kuYilo lweziThuthi

Izakhelo zeenqwelo-mafutha, ezidla ngokubizwa ngokuba yi-chassis, zisebenza njengesiseko kuzo zonke iinkqubo zemoto. Kufuneka bamelane noxinzelelo olukhulu, babambe iimpembelelo zongquzulwano, kwaye baxhase ubunzima besithuthi kunye nabo bakhwele kuso. Iifreyimu zale mihla zenziwe ngobunjineli zisebenzisa izinto eziphucukileyo ezifana nentsimbi ephezulu, ialloys zealuminiyam, kunye neecomposites zecarbon fiber ukulinganisa amandla kunye nokunciphisa ubunzima.

Nangona kunjalo, ukwenza ezi zakhiwo zinzima kufuna ukuchaneka okugqithisileyo. Nokuba ukuphambuka okuncinci kukulungelelaniswa kwe-welding okanye indibano yecandelo kunokuphazamisa ukhuseleko kunye nokusebenza. Iinkqubo zemanuwali zemveli ziyasokola ukuhlangabezana nonyamezelo olungqongqo olufunwa yimigangatho yanamhlanje yeemoto, idala imfuno engxamisekileyo yokuzenzela.

Icandelo lesi-2: Iirobhothi zoShishino kuLwakhiwo lweSakhelo: Izicelo eziphambili

2.1 Ukuphathwa kweMathiriyeli kunye noLungiselelo lwaMacandelo

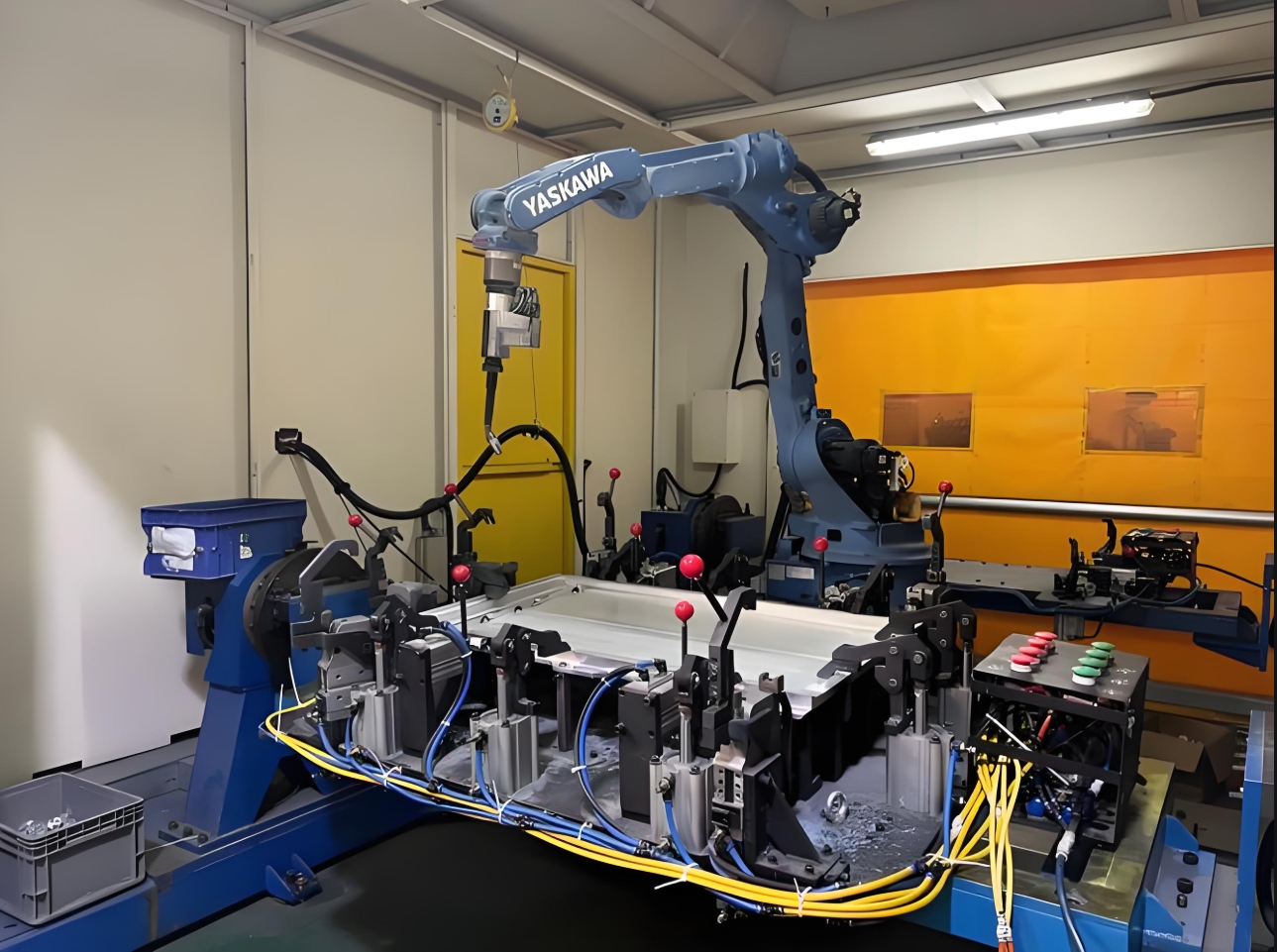

Ukuveliswa kweefreyimu zeemoto kuqala ngokulungiswa kwezinto eziluhlaza. Iirobhothi zemizi-mveliso zixhotyiswe ngezinto zokubamba eziphambili kunye neenkqubo zombono zigqwesa ekuphatheni amashiti esinyithi esikhulu, iityhubhu, kunye nezinto ezenziweyo. Umzekelo:

- Ukuguqulwa kweentsimbi zeshiti: Iirobhothi ezisikwe ngaphambili kunye neentsimbi zentsimbi okanye i-aluminium sheets kwi-frame rails, crossmembers, kunye nezibiyeli ezinokuchaneka kwe-sub-millimeter.

- Ukuphathwa kwezinto ezihlanganisiweyo: Iirobhothi ezisebenzisanayo (i-cobots) zilawula ngokukhuselekileyo izinto ezilula kodwa ezibuthathaka njenge-carbon fiber, ukunciphisa inkunkuma kunye nephutha lomntu.

2.2 Ubuchwephesha beWelding kunye nokuJoyina

I-Welding ihlala isesona sigaba sinzima kakhulu kwirobhothi ekwenzeni isakhelo. Iinkqubo zokuwelda iirobhothi zale mihla zihambisa ulungelelwano olungenakuthelekiswa nanto kumawakawaka amanqaku e-weld:

- Ukumelana nendawo yokuwelda: Iirobhothi ze-Multi-axis zenza i-speed spot welding kwizakhelo zentsimbi, ziqinisekisa amandla adibeneyo afanayo.

- Ukuwelda kweLaser: Iirobhothi ezichanekileyo ezixhotyiswe ngeentloko ze-laser zenza ukudibanisa okungenamthungo kwiifreyimu ze-aluminium, ukunciphisa ukuphazamiseka kwe-thermal.

- Ukusetyenziswa kweAdhesive: Iirobhothi zisebenzisa i-adhesives yesakhiwo kwiipateni ezintsonkothileyo kwibhondi ye-hybrid metal-composite frames, inkqubo ephantse ingenzeki ukuyiphindaphinda ngesandla.

Isifundo: I-automaker yaseYurophu ehamba phambili yanciphisa iziphene ze-welding nge-72% emva kokuthunyelwa kweerobhothi ze-6-axis kunye nokulungiswa kwendlela yokulungisa, ekwazi ukulungelelanisa iiparitha ze-weld ngexesha langempela ngokusekelwe kwimpendulo yenzwa.

2.3 INdibano kunye noManyano

Indibano yesakhelo ibandakanya ukudibanisa ukunyuswa kokumiswa, izibiyeli ze-injini, kunye namacandelo okhuseleko. Iirobhothi ezinengalo ezimbini zilinganisa ubuchwephesha bomntu ekubopheni iibholithi, ukufaka iibhutsi, kunye nokulungelelanisa ii-subassemblies. Iinkqubo ezikhokelwa ngumbono ziqinisekisa ukuba amacandelo abekwe ngaphakathi kwe-± 0.1 mm ukunyamezela, okubalulekileyo ekugcineni ukulungelelaniswa kwe-drivetrain.

2.4 UQinisekiso loMgangatho kunye neMetrology

Ukuhlolwa kwasemva kwemveliso kubalulekile ukuze kuthotyelwe imigaqo yokhuseleko. Iinkqubo zeRobhothi ngoku ziyasebenza:

- Ukuskena kwe-laser ye-3D: Imephu yeerobhothi zonke zesakhelo zejometri zokubona ukungachaneki kwe-warping okanye i-dimensional.

- Uvavanyo lwe-ultrasonic: Iiprobe ezizenzekelayo zihlola ingqibelelo ye-weld ngaphandle kokonakalisa umphezulu.

- I-AI-powered defect monitoring: Ii-algorithms zokufunda ngomatshini zihlalutya ukutya kwekhamera ukuchonga ama-micro-cracks okanye ukungahambelani kokwambathisa.

Icandelo lesi-3: I-Advantages ye-Robotic Automation kwiMveliso yeSakhelo

3.1 Ukuchaneka nokuPhindwa kwakhona

Iirobhothi zoshishino ziphelisa ukuhluka kwabantu. Iseli enye ye-robotic welding inokugcina i-0.02 mm ukuphindaphinda kuyo yonke imijikelezo ye-24/7 yokuvelisa, iqinisekisa ukuba isakhelo ngasinye sidibana neenkcukacha zoyilo.

3.2 Ukhuseleko loMsebenzi olomeleziweyo

Ngokuzenzekelayo imisebenzi enobungozi efana ne-welding overhead okanye ukuphakamisa okunzima, abavelisi baye babika ukucutha kwe-60% yokulimala emsebenzini okunxulumene nokwenziwa kwesakhelo.

3.3 UFaneka kwiindleko

Ngelixa utyalo-mali lokuqala lubalulekile, iirobhothi zinciphisa iindleko zexesha elide ngokusebenzisa:

- 30-50% amaxesha omjikelezo okhawulezayo

- I-20% yenkunkuma yezinto ezisezantsi

- I-40% yokunciphisa iindleko zokusebenza kwakhona

3.4 Ukuqina kunye nokuguquguquka

Iiseli zerobhothi zemodyuli zivumela abavelisi ukuba bahlengahlengise ngokukhawuleza imigca yemveliso yoyilo lwesakhelo esitsha. Ngokomzekelo, iifreyimu zemoto yombane (EV) ezineentsimbi ezivaliweyo zebhetri zinokudibaniswa kwiinkqubo ezikhoyo kunye nexesha elincinci lokunciphisa.

Icandelo lesi-4: Ukoyisa imingeni kwiRobotic Frame Manufacturing

4.1 Imiba yokuhambelana kwezinto

Ukutshintshela kwiifreyimu zezinto ezininzi (umzekelo, i-steel-aluminiyam hybrids) ifuna iirobhothi zijongane neendlela zokudibanisa ezingafaniyo. Izisombululo ziquka:

- Iintloko ze-Hybrid welding ezidibanisa i-arc kunye ne-laser teknoloji

- Izibambi zeMagnetic zokuphatha iintsimbi ezingenayo i-ferrous

4.2 Ukuntsonkotha kweNkqubo

Inkqubo yerobhothi engaxhunyiwe kwi-intanethi (OLP) ngoku ivumela iinjineli ukuba zilinganise kwaye ziphucule ukuhamba komsebenzi kwerobhothi ngedijithali, ukucutha ixesha lokugunyazisa ukuya kuthi ga kwi-80%.

4.3 Imingcipheko yeCybersecurity

Njengoko imveliso yesakhelo isiya iqhagamshelwa ngakumbi nge-Industrial IoT, abavelisi kufuneka baphumeze iiprothokholi zonxibelelwano ezifihliweyo kunye nohlaziyo oluqhelekileyo lwe-firmware ukukhusela uthungelwano lwerobhothi.

Icandelo lesi-5: Ikamva lokuVeliswa kweSakhelo seRobhothi

5.1 I-AI-Driven Adptive Manufacturing

Iirobhothi zesizukulwana esilandelayo ziya kusebenzisa ubukrelekrele bokwenziwa:

- Izixhobo zokuzilinganisa ngokusekelwe kubukhulu bezinto eziphathekayo

- Qikelela kwaye ubuyekeze ukunxitywa kwesixhobo

- Yandisa ukusetyenziswa kwamandla ngexesha lemfuno ephezulu

5.2 INtsebenziswano yoLuntu neyeRobhothi

I-Cobots ene-force-limited joints iya kusebenza kunye neengcali zohlengahlengiso lokugqibela lwesakhelo, ukudibanisa ukwenza izigqibo zabantu kunye ngokuchanekileyo kwerobhothi.

5.3 IMveliso eZinzileyo

Iinkqubo zerobhothi ziya kudlala indima ebalulekileyo ekufezekiseni ukwenziwa kwesetyhula:

- Ukucinywa okuzenzekelayo kokuphela kobomi bezakhelo zokuphinda zisetyenziswe

- Ukubekwa kwezinto ezichanekileyo zokunciphisa ukusetyenziswa kwemathiriyeli ekrwada

Ukuqukumbela

Ukuhlanganiswa kweerobhothi zoshishino kwimveliso yesakhelo semoto kubonisa okungaphezulu nje kokuqhubela phambili kwezobuchwepheshe-kubonisa utshintsho olusisiseko kwindlela izithuthi ezikhulelwa ngayo kunye nokwakhiwa. Ngokuzisa ngokuchanekileyo, ukusebenza kakuhle, kunye nokuguquguquka, iinkqubo zerobhothi zixhobisa abavelisi ukuba bahlangabezane neemfuno eziguqukayo zezithuthi ezikhuselekileyo, ezikhaphukhaphu kunye nezizinzileyo. Njengoko i-AI, izinzwa ezihambele phambili, kunye nobuchwepheshe obuluhlaza buqhubeka bukhula, intsebenziswano phakathi kwerobhothi kunye nobunjineli beemoto ngokungathandabuzekiyo iya kuqhuba ishishini ukuya kumanqanaba angazange abonwe ngaphambili.

Kwiinkampani ezisebenza ngerobhothi kwimizi-mveliso, olu tshintsho lubonelela ngamathuba amakhulu okusebenzisana nabenzi bee-automaker ekuchazeni kwakhona ikamva lokushukuma — isakhelo esenziwe ngokugqibeleleyo ngexesha.

Ukubalwa kwamagama: 1,480

ImiGaqo engundoqo: Iirobhothi zesakhelo semoto, iinkqubo zokuwelda iirobhothi, i-AI kwimveliso, iirobhothi ezisebenzisanayo, imveliso ezinzileyo

SEO iingcebiso: Bandakanya inkcazo yemeta ejolise "kwisakhelo semoto esizihambelayo" kunye "neirobhothi zamashishini ze chassis yemoto." Sebenzisa amakhonkco angaphakathi kwizifundo ezihambelanayo okanye amaphepha emveliso.

Ixesha lokuposa: Mar-26-2025