Ngophuhliso lobugcisa berobhothi, ngakumbi nangakumbi amashishini aqala ukonwabela ulwahlulo lwe-welding ekrelekrele, kuba ibonelela ngetekhnoloji engabizi kakhulu kumashishini ukuphumeza ubukrelekrele, ulwazi, kunye nokuzenzekelayo kweemveliso ze-welding. Kushishino olunzima, i-arc welding irobhothi yokuwelda indawo yokusebenza, edibanisa itekhnoloji yerobhothi, inkqubo yokuwelda, uyilo lomatshini, itekhnoloji yokuva, itekhnoloji yolawulo oluzenzekelayo, kunye nenkqubo ye-MES kunye nolunye uqeqesho, ikakhulu isombulula imfuno yezixhobo ezizenzekelayo kwinkqubo ye-welding kwimveliso yeshishini. Ngokuqinisekileyo, kungakhathaliseki ukuba yiyiphi imboni yokufezekisa i-welding ehlakaniphile, ngokuqhelekileyo ayinakuhlukaniswa kwi-high-quality welding wire, kuba umgangatho wocingo, uya kuba nefuthe elikhulu ekuzinzeni kwe-wire feed kwinkqubo ye-welding, umgangatho we-welding, njl.

Ukwakhiwa kwerobhothi ye-arc ye-arc

Irobhothi yoshishino iyacwangciswa, i-anthropomorphic, jikelele, kwaye ikrelekrele, kwaye isetyenziswe ngokubanzi kumashishini amaninzi. Iirobhothi zoshishino zinokudibaniswa kunye nezinye izixhobo zokwenza izikhokelo zezicelo zerobhothi ezahlukeneyo, izicelo eziqhelekileyo zibandakanya i-welding, ipeyinti, indibano, ukuqokelela kunye nokubekwa (okufana nokupakisha, i-palletizing, kunye ne-SMT), ukuhlolwa kwemveliso kunye nokuvavanya, njl.

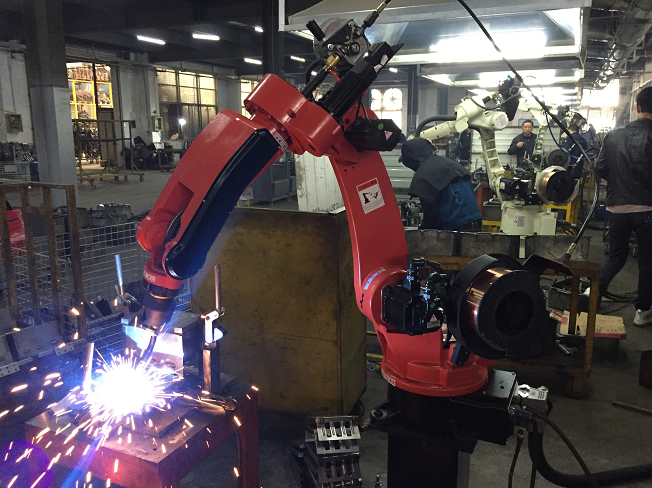

I-robot ye-arc welding ikakhulu yenziwe ngezixhobo ze-arc welding kunye nenkqubo yerobhothi. Inkqubo yerobhothi iqulunqwe ngumzimba werobhothi kunye nekhabhinethi yokulawula (i-hardware kunye ne-arc welding software, njl. njl.) Isixhobo se-arc welding siqulunqwe ngumbane we-welding, i-wire feeding mechanism, i-welding gun kunye nezinye iindawo. Iirobhothi ezikrelekrele ngakumbi zixhotyiswe ngelaser okanye izinzwa zombono kunye neenkqubo zokulawula umbane. Indawo yokusebenza yerobhothi ye-arc ye-welding iboniswe kuMfanekiso 1.

Isicelo esiqhelekileyo se-2 arc welding workstation yerobhothi

(1) Indawo yokusebenza yerobhothi elula yokuwelda Eyona ndlela ilula ye-arc welding irobhothi yokusebenzela yirobhothi enye, unikezelo lwamandla omnye welding, umpu welding kunye nesixhobo esilula. Olu hlobo lwe-robot welding workstation yeyona nto isisiseko, kodwa kunye namanye amacandelo emveliso yerobhothi entsonkothileyo. Umzobo we-2 ubonisa indawo yokusebenza yerobhothi ye-arc elula. Irobhothi yale ndawo yokusebenzela yiFanuc irobhothi, eyi actuator yayo yonke inkqubo yokusebenzela. Ikhabhinethi yolawulo liziko lobuchopho lenkqubo yerobhothi, ejongene nedatha kunye nokuhanjiswa komqondiso we-actuator kunye nokulawula ukuhamba kwe-activator. Isixhobo sokufundisa lujongano lwekhompyutha yomntu, apho i-debugger inokulungisa inkqubo ngokweemfuno zemveliso. Unikezelo lwamandla welding luthatha i-Lincoln welder, kwaye irobhothi inokunxibelelana nothungelwano lwe-Arclink, olulungele ukuhanjiswa komqondiso we-welding phakathi kwerobhothi kunye ne-welding.TBI ye-welding gun kunye nomatshini wokuwelda, i-welding wire kunye ne-tooling zenza indlela epheleleyo yokufikelela kwi-welding workpiece.

Ngokwakhiwa kweendawo zokusebenza zerobhothi zokuwelda, ezinye iimveliso zamashishini ezilula ziyakwazi ukufezekiswa i-welding ezenzekelayo. Logama nje indawo yemveliso kwisixhobo ibekwe kakuhle kwimveliso ethile, inkqubo yokufundisa i-intanethi ye-welding seam trajectory iyaqhutywa, kunye nenkqubo yeeparameters zemveliso eyomeleleyo igalelo, irobhothi inokuqaliswa ukuqonda ukuwelda okuzenzekelayo kwemveliso. Ukuwelda kwepleyiti enzima kunye nale ndawo yokusebenzela intle imile kwaye ilungile kumgangatho.

Olu hlobo lwerobhothi yokuwelda indawo yokusebenzela ilungele ngokukodwa i-welding encinci ye-workpiece, efana nepleyiti ethe tye, ipleyiti engqukuva kunye nezinye i-workpiece, ukuguquguquka okuqinileyo, ukuhambelana ngakumbi; Nangona kunjalo, kukho ingxaki ngolu hlobo lweendawo zokusebenza: ngalo lonke ixesha iimveliso zifuna ukulayishwa kwaye zithulwe ngesandla, kwaye iimveliso azikwazi ukunyanzeliswa ngokuzenzekelayo, okukhokelela ekungaphumeleli kwayo yonke i-robot welding workstation ukuphumeza ukuwelda okuzenzekelayo ngokupheleleyo ngengqiqo yokwenene.

ukuwelda irobhothi ukuwelda indawo yokusebenza ukongeza elula ukuwelda workstation izixhobo ezisisiseko, kwakhona ixhotyiswe isixhobo sombane lwangaphandle, iPC touch screen, jig, inkqubo laser positioning kunye nesixhobo ukuqokelelwa uthuli kunye nenkqubo yokubeka iliso njalo, ngokusebenzisa la macandelo ukwakha ngakumbi epheleleyo ukuwelda arc ukuwelda indawo yokusebenza yerobhothi, Yibize ngokuba yirobhothi ekrelekrele indawo yokusebenzela. workpiece, kwaye ngaphandle nawuphi na abasebenzi ukuba bathathe inxaxheba kuhlengahlengiso lwezixhobo, oko kukuthi, ukuqonda umsebenzi wokwenene unmanned.

Ixesha lokuposa: Mar-25-2022