Ukusetyenziswa kweerobhothi ze-welding kufuneka kulawule ngokungqongqo umgangatho wokulungiselela iinxalenye kunye nokuphucula ukuchaneka kwendibano ye-weldments. Umgangatho womphezulu, ubungakanani begroove kunye nokuchaneka kwendibano yamacandelo kuya kuchaphazela isiphumo sokulandelela i-welding seam. Umgangatho wokulungiswa kweengxenye kunye nokuchaneka kwendibano ye-weldment inokuphuculwa ukusuka kule miba ilandelayo.

(1) Qokelela inkqubo yokuwelda ekhethekileyo yeerobhothi zokuwelda, kwaye wenze imimiselo yenkqubo engqongqo kubungakanani bamalungu, i-weld grooves, kunye nemilinganiselo yendibano. Ngokuqhelekileyo, ukunyamezela kwamalungu kunye nobukhulu begroove kulawulwa ngaphakathi kwe-± 0.8mm, kwaye impazamo yedimension yendibano ilawulwa ngaphakathi kwe-± 1.5mm. Amathuba okuba neziphene ze-welding ezifana ne-pores kunye ne-undercuts kwi-weld ingancitshiswa kakhulu.

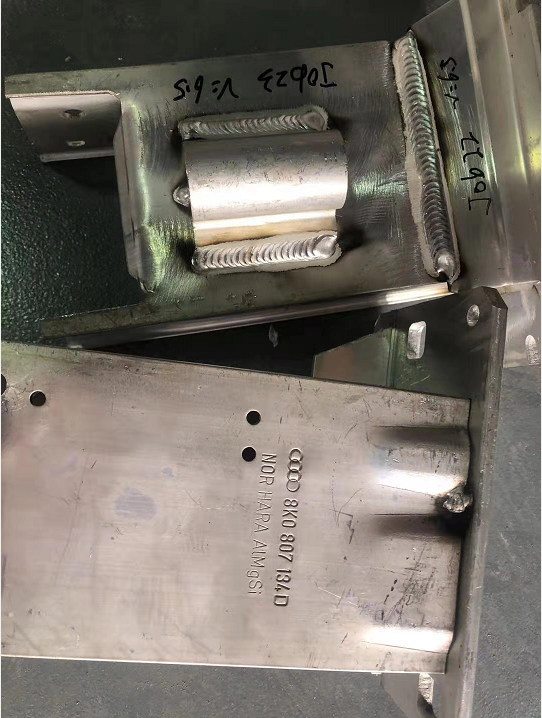

(2) Sebenzisa izixhobo zendibano ezichanekileyo zokuphucula ukuchaneka kwendibano ye-weldments.

(3) I-Welding seams kufuneka ihlanjululwe, ingabi neoli, i-rust, i-welding slag, i-slag yokusika, njl., kunye ne-primers ethengiswayo iyavunyelwa. Ngaphandle koko, kuya kuchaphazela izinga lempumelelo ye-arc ignition. I-Tack welding iyatshintshwa ukusuka kwi-electrode welding ukuya kwi-gas shielded welding. Kwangaxeshanye, iindawo zokuwelda ziyagudiswa ukunqanda intsalela ye-slag crusts okanye iipores ngenxa ye-welding ye-tack, ukunqanda ukungazinzi kwe-arc kunye nokutshiza.

Ixesha lokuposa: Sep-11-2021