Impembelelo ye-welding ye-robot welding ichatshazelwa yimiba emininzi. Abathengi abaninzi baya kudibana nezinye iingxaki ngaphezulu okanye ngaphantsi ngaphambi kokuba babe nobuchule bokusebenzisa iirobhothi ze-welding. Ngokwenene, ezi ngxaki zibangelwa ukusebenza okungafanelekanga okanye izicwangciso zerobhothi ezingafanelekanga, kwaye zinokusombululwa ngohlengahlengiso olufanelekileyo. Okulandelayo, umhleli uya kukuthatha ukuba uthathe isitokhwe seengxaki ezithile ezihlala zisenzeka ekusebenziseni iirobhothi zokuwelda zaseYunhua kunye nezisombululo ezinxulumeneyo.

1. I-arc engaphumelelanga iqala ngexesha le-welding

1. I-arc ayikaqalisi

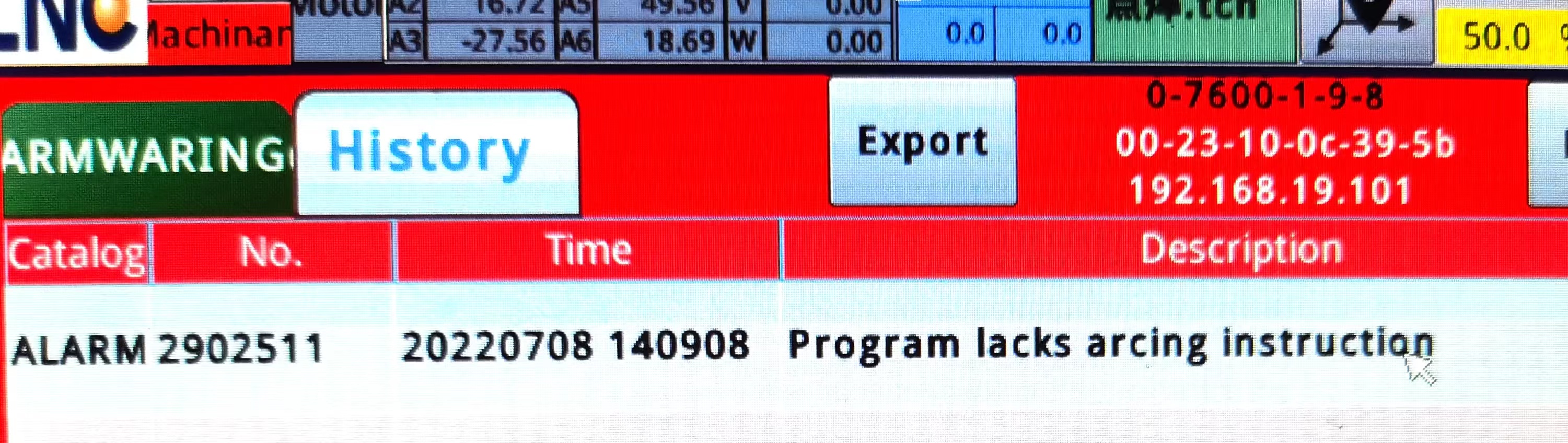

Isizathu: Akukho myalelo uqalisayo we-arc phambi kokuphumeza umyalelo ophelisayo we-arc kwinkqubo ehleliweyo.

Indlela yokuqhuba: Jonga ukuba wongeze omnye umyalelo ophelayo we-arc okanye umyalelo omnye oqalayo we-arc

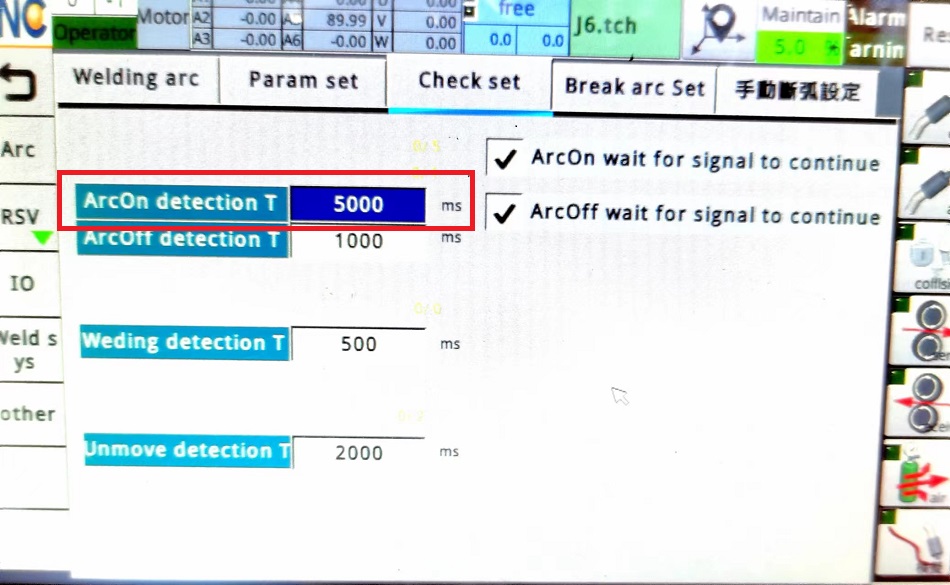

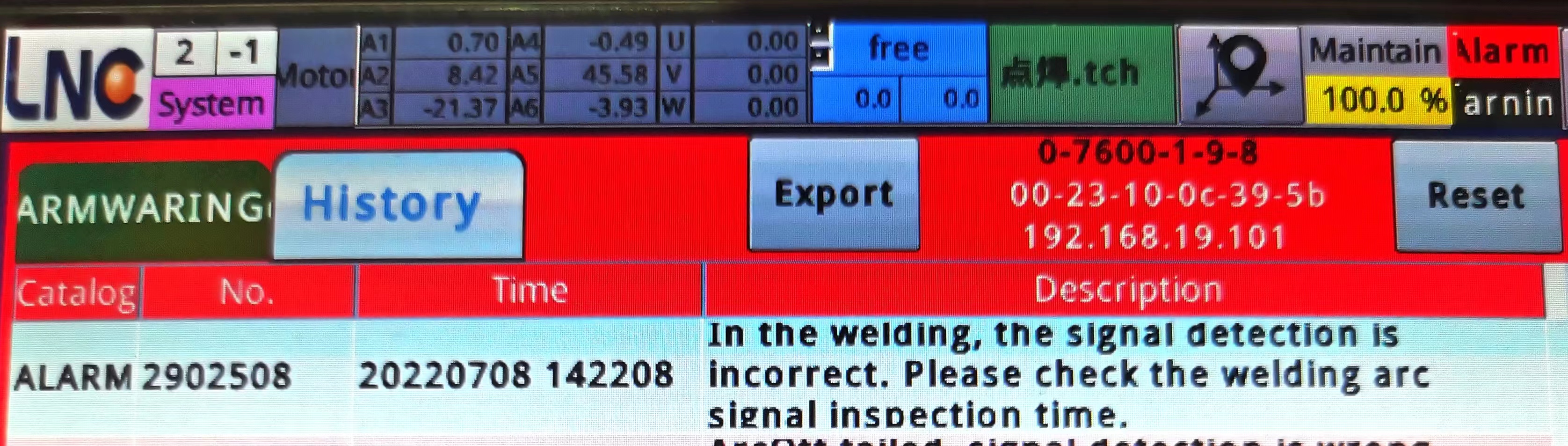

2. Ayiphumelelanga ukuqalisa i-arc, ukufunyanwa komqondiso akulunganga

3. I-Arc yocingo oluthosiweyo

isizathu:

1) Ukungafani kwangoku kunye nombane

Indlela yokucubungula: Sidinga ukuseta i-current efanelekileyo kunye ne-voltage ngokobukhulu bokwenene bomsebenzi kunye nomatshini we-welding

2) Ubude bocingo lwe-welding bude kakhulu

Indlela yonyango: Ngokuqhelekileyo, ubude bocingo lwe-welding yi-10 ukuya kwi-15 ububanzi be-welding wire, kwaye ubude obufanelekileyo bocingo lwe-welding bukhethwa ngokuhambelana nobubanzi be-welding wire.

Umbane omncinci kakhulu ukhokelela kwiiwelds ezingalinganiyo

Isiqhelo sangoku kunye ne-voltage, intle kwaye iqinile i-weld

Ukuphela kwetotshi ye-welding kuya kuba yibhola yocingo

I-welding torch end wire ikwimeko entle emva kwewelding eqhelekileyo

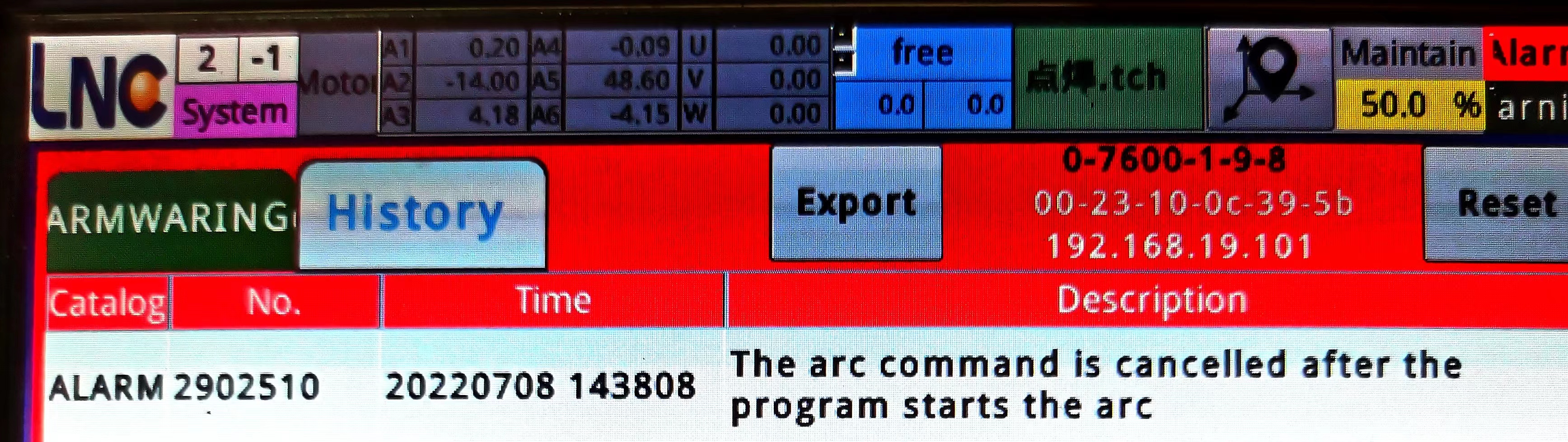

4. I-phenomenon yokucima i-arc ngokuzenzekelayo kwenzeka emva kwe-arcing

Isisombululo: Khangela ukuba kukho ingxaki ngexesha leparameter engashukumiyo ukusetwa kwexesha, kwaye khangela ukuba itotshi ye-welding ihambile.

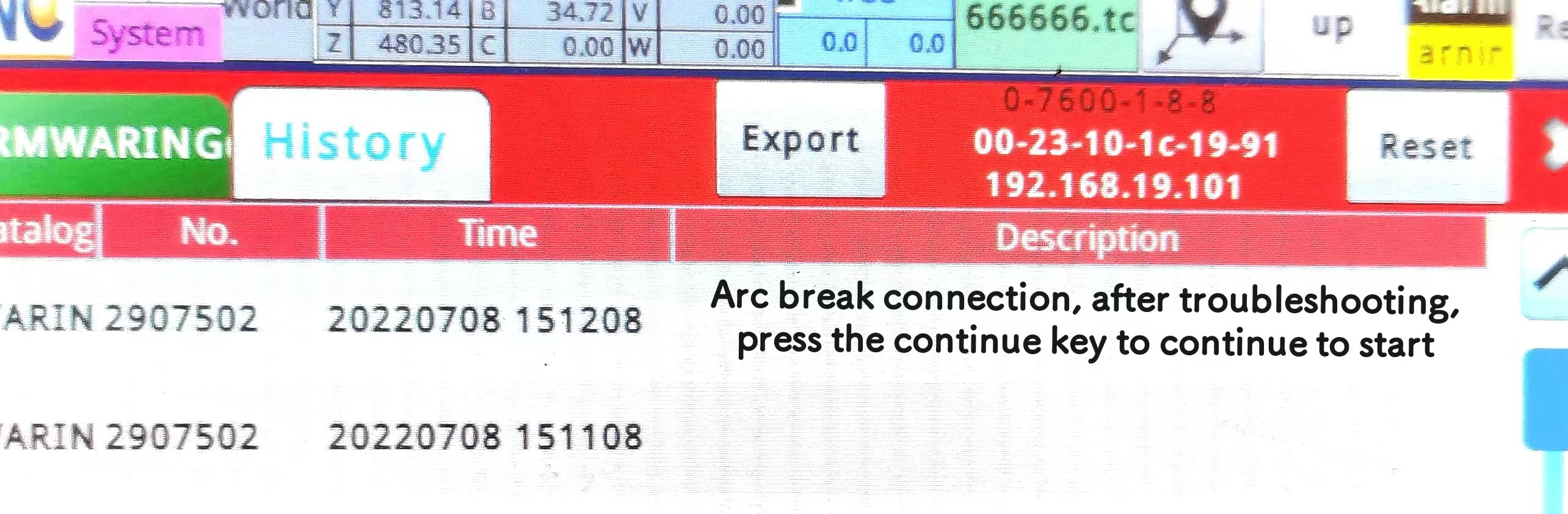

2. Ikhefu le-arc lenzeka ngexesha le-welding

isizathu:

1. Ukuba ucingo lwe-welding aluchukumisi i-workpiece, i-arc breaking alarm iya kuqaliswa

Indlela yonyango: Lungisa indawo yocingo lwe-welding kunye ne-workpiece, ukwenzela ukuba ucingo lwe-welding luqhagamshelane ngokupheleleyo nomsebenzi ngexesha lenkqubo ye-welding. (Kodwa akufuneki ukuba isondele kakhulu kwi-workpiece, inokukhokelela kwi-welding ngokusebenzisa i-workpiece)

2. Indlela ye-welding engafanelekanga ibangela ukuba intloko yompu iphakame ngokuzenzekelayo ngenxa yokungqubana

Isisombululo: phinda usete indlela ye-welding

3. Iingcingo ezilungileyo kunye nezibi zomatshini we-welding zidibene kakubi

Indlela yoNyango: Jonga imeko yocingo lweengcingo ezilungileyo kunye nezibi

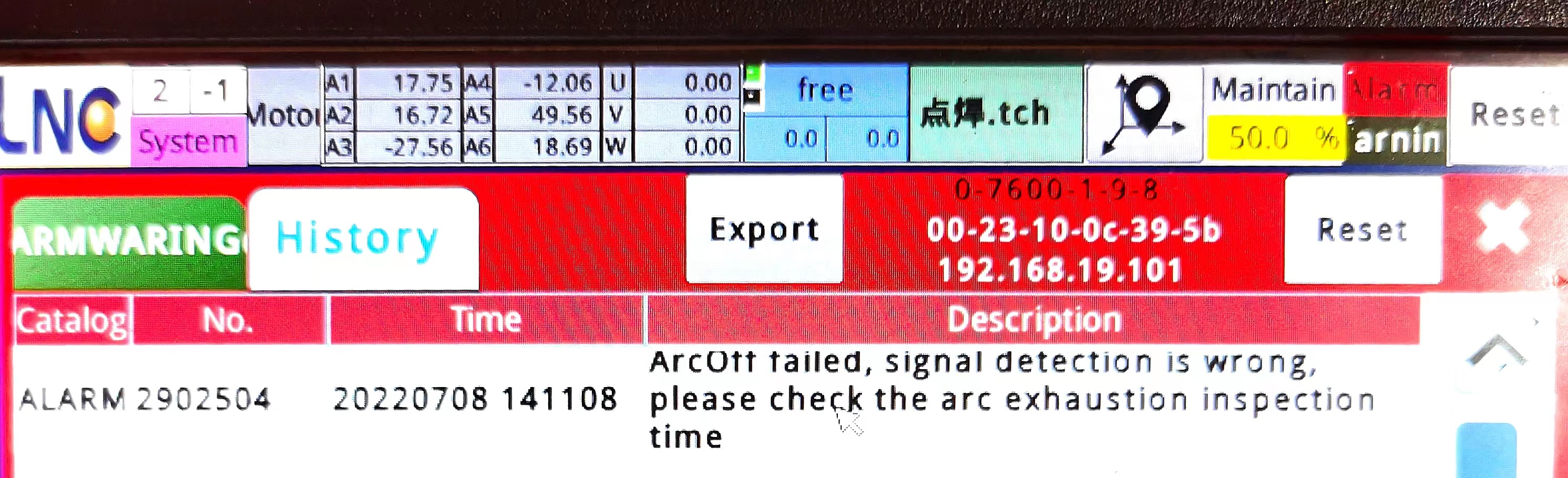

3. Izizathu zokungaphumeleli kokuphela kwe-arc emva kwe-welding

1. Ukungaphumeleli kwe-arc, impazamo yokufumanisa umqondiso

Isizathu: Umatshini we-welding awuzange ufumane umqondiso kwi-robot, obangela ukuba i-robot ingaphumeleli ukuvala i-arc.

Indlela yokwenza:

(1) Khangela ukuba iiparamitha zokuseta zifanelekile kusini na

(2) Jonga isignali ye-IO, kwaye ukhangele ukuba umqondiso wendawo yokuphelisa iyinto engaqhelekanga. Ukuba uphawu lwe-I point luhlala lubonisa ON.

(3) Khangela ukuba kukho isiphaluka esifutshane emgceni nokuba ngaba ucingo olusezantsi luqhagamshelwe ngokungaqhelekanga

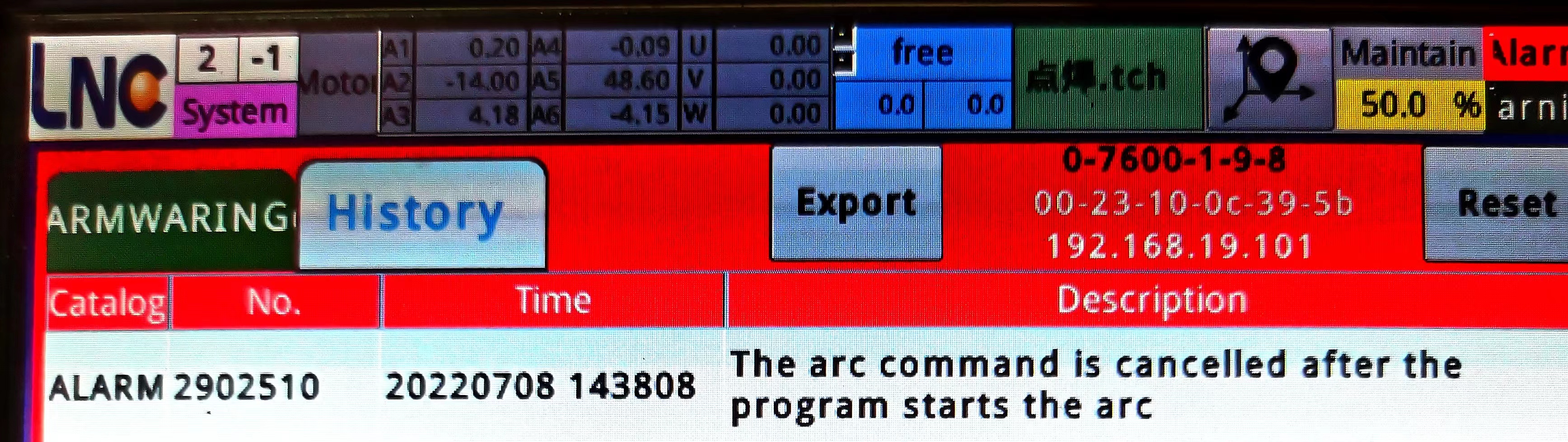

2. Akukho myalelo wokumisa we-arc usetwa emva kogwayimbo lwe-arc

Isizathu: Xa le alamu isenzeka kwipendant yokufundisa, khangela ukuba uyalibala na ukongeza umyalelo ophelayo we-arc

Indlela yokuqhubekekisa: yongeza i-arc isiphelo somyalelo emva komyalelo wokuqalisa we-arc kwinkqubo

Lo mbandela ikakhulu wazisa i-arc-ukuqala, i-arc-breaking kunye ne-arc-ephela iingxaki ezinxulumene ne-Yunhua welding irobhothi ngexesha lenkqubo ye-welding. Ukuba abasebenzisi bahlangabezana neengxaki ezinjalo ngexesha lokusetyenziswa, banokubhekisela kwizisombululo. Ukuba azinakusonjululwa, nceda ufune amagcisa aseYunhua kwangethuba. Nceda.

Ukuba ufuna ukwazi iingxaki eziqhelekileyo kunye nezisombululo ze-Yunhua Robot, nceda ubeke ingqalelo kwi-Akhawunti ye-Yunhua Robot esemthethweni.

I-Yunhua welding irobhothi yirobhothi ezenzekelayo edibanisa i-welding yemisebenzi emininzi efana ne-gas shielded welding, i-argon arc welding, i-plasma cut, kunye ne-laser welding. Inokuguquguquka okuphezulu, ukuguquguquka okunamandla, ukusebenza kakuhle kwe-welding kunye nomgangatho ozinzileyo we-welding, kwaye inokusetyenziswa ngokubanzi kwiinkalo ezahlukeneyo. Okufana nokuveliswa koomatshini, ukwenziwa kweemoto, izinto zombane ezichanekileyo kunye nokwembiwa kwamalahle kunye nezinye iinkalo.

Ixesha lokuposa: Jul-15-2022